190-01115-01

G3X/G3X Touch Installation Manual - Engine/Airframe Sensor Installation

Rev. AC

Page 23-20

23.3.5 Pressure (Fuel, Manifold, Oil, and Coolant)

General Installation Guidance –

The specified pressure transducers provide for two different mounting

options:

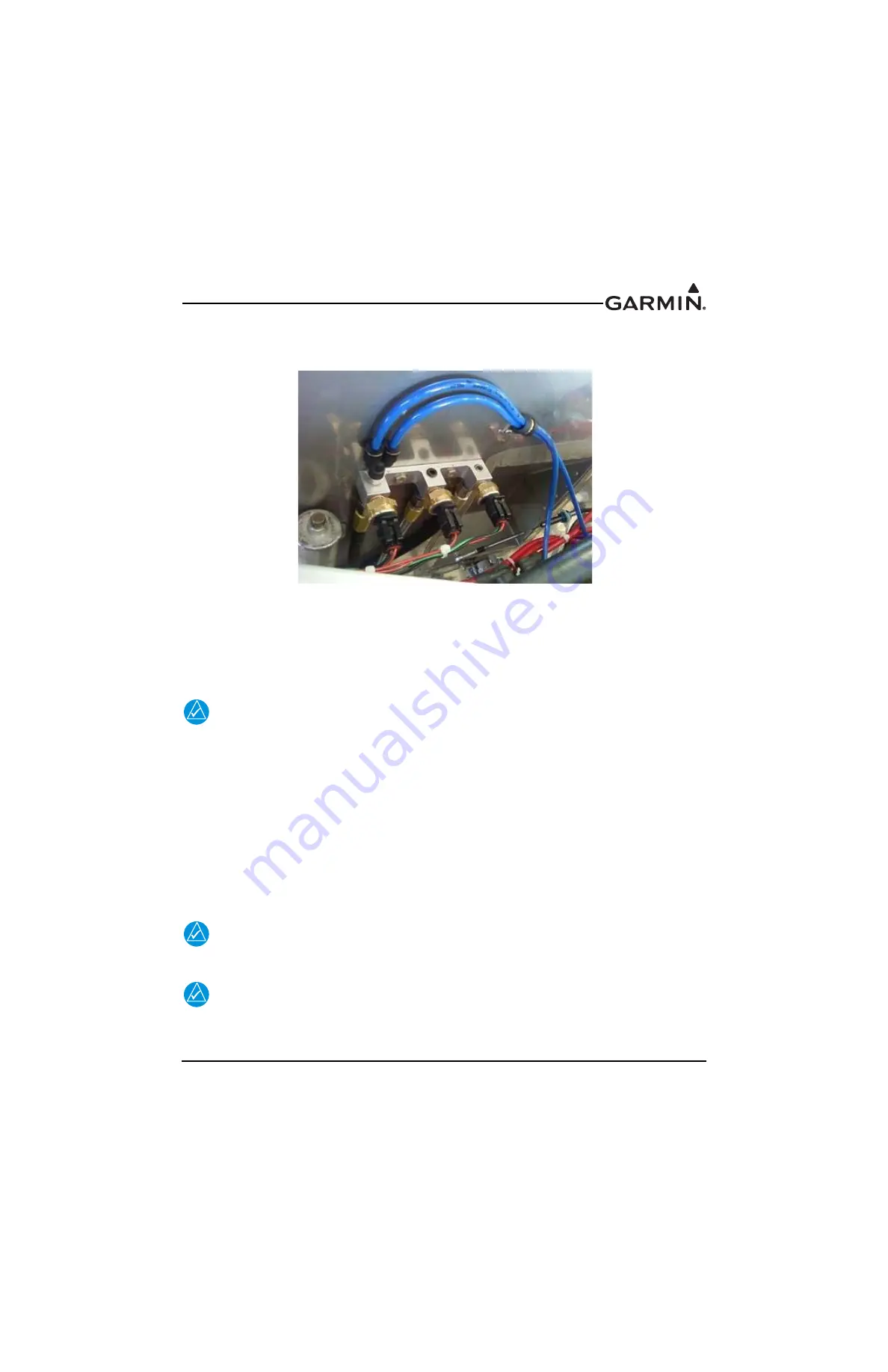

Figure 23-11 Pressure Transducer Mounting Block

a) Sensor body secured to the engine mount or firewall via an appropriately sized Adel clamp

(preferred)

OR

b) Mounted to a transducer mounting block located on the firewall. UMA sensor mounting

may require the use of a stainless steel AN911 fitting (union).

NOTE

To minimize the possibility of cracking or breaking of the transducer due to vibration, the

sensor should not be mounted directly to the engine. Mechanical failure of the transducer

could result in loss of engine pressure for the sensed parameter (oil, fuel, manifold,

coolant).

Once a suitable sensor mounting arrangement has been identified, the following installation

procedures should be followed:

1. Mount the sensor using one of the two methods noted above.

2. Refer to the applicable engine manual to identify the appropriate connecting port on the engine for

the parameter being sensed. Once identified, use appropriate aircraft-grade hoses and fittings to

connect the corresponding port on the engine to the sensor. The male threads on Kavlico sensors

are designed to mate with a 1/8” NPT female thread. The female threads on UMA sensors are

designed to mate with a 1/8” NPT male thread.

NOTE

The fuel and oil pressure fittings on the engine port should have a restrictor hole where

appropriate to minimize potential fluid loss in the event of breakage.

NOTE

A restrictor or snubber fitting (not available from Garmin) may be installed to dampen

manifold pressure fluctuations. One example is the PS-8G fitting from Omega

Engineering.