·92·

Operating manual

CNC 8055

CNC 8055i

5.

ED

IT

·T· M

ODEL

S

OFT

: V02.2

X

Edit

Programming in Polar coordinates requires editing the Polar origin of each point. The data definition

area offers room to edit this data and the graphic window will show the active Polar origin.

Initiate the session at the profile editor.

"EDIT" softkey

This softkey gives access to the profile editor. It may be used to edit a rectangular or circular profile

or any profile made up of straight or curved sections.

"CONFIGURATION" softkey

Use the [abscissa axis] and [ordinate axis] softkeys to select the editing plane. Use the [Along the

abscissa] and [along the ordinate] softkeys to select the direction of the axes of the plane. To assume

the new configuration, press the "VALIDATE" softkey.

"DISPLAY AREA" softkey

When selecting this option, the following softkey options are shown:

[Zoom +]

To enlarge the image on the screen.

[Zoom -]

To reduce the image on the screen.

[Optimum area]

To show the full profile on the screen.

[Autozoom]

The CNC recalculates the graphics display area or not when the edited

lines go beyond it.

[Part zero]

Always see the part zero.

[Validate]

It assumes the new configuration.

The display area may be moved around with the [

] [

] [

] [

] keys and the zoom may be modified

using the [+] [-] keys. The display area may be modified while editing the profile with the "MODIFY"

softkey.

The editor offers are 5 hotkeys to modify the zoom and the part zero that will be functional when

not editing data.

"FINISH" softkey

This softkey must be pressed once all the sections of the profile have been defined. When pressing

this softkey, the CNC quits the profile editor and adds to the program the ISO-code corresponding

to the profile just edited. See

"End the session with the profile editor."

on page 97.

"SAVE AND CONTINUE" softkey

This softkey saves the profile without having to finish the session with the editor.

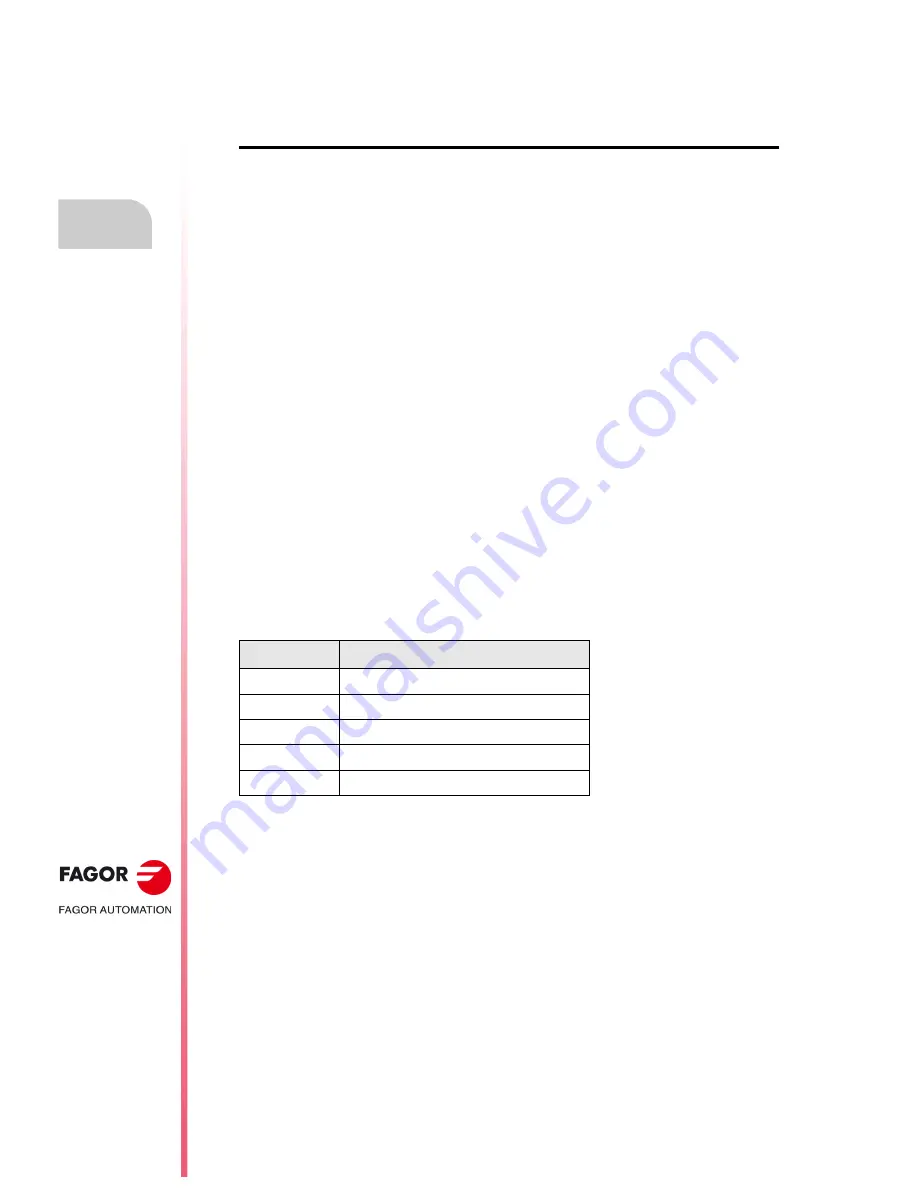

Hotkey

Meaning

+

Zoom +.

-

Zoom -.

*

It changes the Autozoom status.

/

It changes the Part Zero status.

=

It shows the best area.

Summary of Contents for CNC 8055

Page 1: ...CNC 8055 T Operating manual Ref 1705 Soft V02 2x...

Page 6: ...6 Operating manual CNC 8055 CNC 8055i T MODEL SOFT V02 2X...

Page 10: ...18 CNC 8055 CNC 8055i Declaration of conformity and Warranty conditions...

Page 14: ...10 CNC 8055 CNC 8055i Version history...

Page 20: ...16 CNC 8055 CNC 8055i Returning conditions...

Page 22: ...20 CNC 8055 CNC 8055i Additional notes...

Page 24: ...22 CNC 8055 CNC 8055i Fagor documentation...

Page 124: ...124 Operating manual CNC 8055 CNC 8055i 6 MANUAL T MODEL SOFT V02 2X Spindle movement...

Page 134: ...134 Operating manual CNC 8055 CNC 8055i 7 TABLES T MODEL SOFT V02 2X Tool Offset table...

Page 135: ...Operating manual CNC 8055 CNC 8055i TABLES 7 T MODEL SOFT V02 2X 135 Tool Offset table...

Page 138: ...138 Operating manual CNC 8055 CNC 8055i 7 TABLES T MODEL SOFT V02 2X Tool geometry table...

Page 196: ...196 Operating manual CNC 8055 CNC 8055i 10 PLC T MODEL SOFT V02 2X Logic analyzer...

Page 212: ...212 Operating manual CNC 8055 CNC 8055i 11 GRAPHIC EDITOR T MODEL SOFT V02 2X Modifications...

Page 240: ...240 Operating manual CNC 8055 CNC 8055i 13 DIAGNOSIS T MODEL SOFT V02 2X Interesting notes...

Page 253: ...Operating manual CNC 8055 CNC 8055i 14 T MODEL SOFT V02 2X 253...

Page 254: ...254 Operating manual CNC 8055 CNC 8055i 14 T MODEL SOFT V02 2X...

Page 255: ......