C6.1.6/0117-1017/E

23

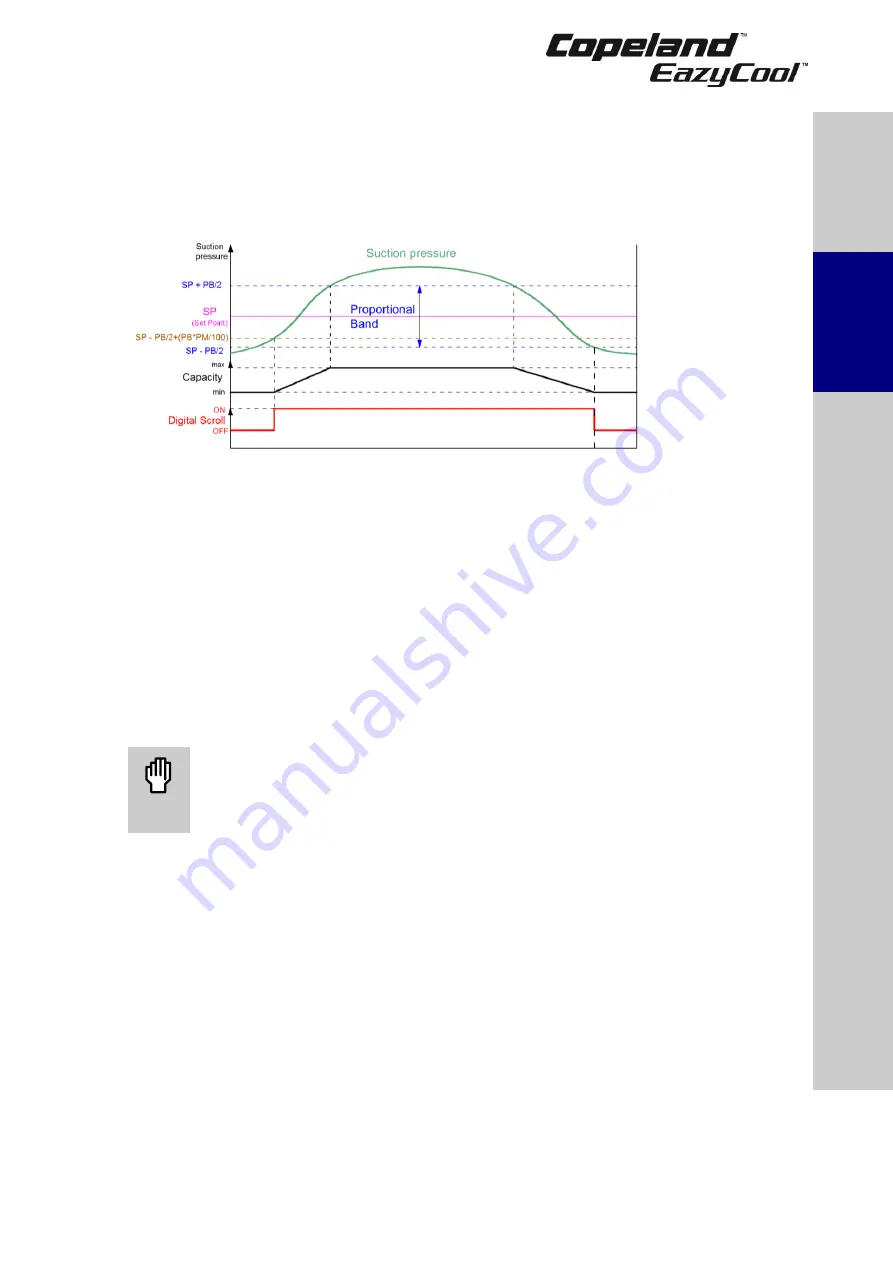

2.13 Digital operation

A Digital unit is able to operate in a part-load mode. Part-load operation is achieved by loading and

unloading of the Digital scroll compressor for certain periods of time (time cycles). The cycle of time

can be chosen between 10 and 30 seconds. Example: if the time cycle is 20 seconds at 50% of

capacity request, the compressor will run for 10 seconds loaded and 10 seconds unloaded. For

proper commissioning of the Digital unit the following diagram must be considered:

Figure 13: Digital operation

The regulation starts when the suction pressure (

AI1

) increases and reaches the value

(SP-PB/2+(PB*PMI)/100)

or

(C16-C17/2+(C17*C24)/100). Within the

adjustment range

(SP-PB/2~SP+PB/2) or (C16

–C17/2 ~ C16+C17/2) the Digital scroll compressor is activated in PWM

mode according to the value of the control variable.

When the pressure is higher than (SP + PB/2) or (C16 + C17/2) then the TRIAC output is at maximum

capacity. When the pressure is lower than (SP + PB/2) or (C16 + C17/2) but higher than (SP-PB/2)

the Digital Scroll compressor modulates the capacity according to the proportional band. If the

pressure is lower than (SP-PB/2)/ (C16-C17/2) the Digital Scroll compressor switches off.

NOTE: When the digital valve on the compressor is discharged the compressor is loaded.

NOTE: At start-up the valve is energized for Sut/C20 start-up time, ie, time interval with the

digital valve energized before regulation starts. It ranges from 0 to 10 seconds.

2.14 Pump-down

– General

CAUTION

System pressure below atmospheric pressure! Compressor damage!

Never operate the system below atmospheric pressure. There is a risk of

malfunction of the controller in deep vacuum operation which can cause

compressor damage.

Pump-down functionality is provided by the XCM25D controller for ZXME and ZXLE units only. It is

not released for Digital units ZXDE.

NOTE: Depending on the compressor and/or system design an increase of suction pressure

is possible when the unit stops. Therefore, pump-down operation requires higher differences

between cut-in and cut-out setpoints. These values must be adjusted according to

application.

2.14.1 External pump-down

– Without XCM25D integration (not available on ZXDE units)

The easiest solution for pump-down is to install a solenoid valve in the liquid line (not part of the

standard delivery) and to control it directly with the room thermostat or other external devices. The

settings on the unit for compressor cut-in and cut-out (

C01

&

C02

) can easily be adjusted for pump-

down. The disadvantage of this easy solution is that the controller is not informed that there is a

solenoid valve installed and therefore some protection features of the controller, eg, maximum pump-

down time in case of blocked solenoid, will not work.

2.14.2 Pump-down by the unit controller (not available on ZXDE units)

In case of pump-down by the unit controller (available only for ZXME and ZXLE units) the user needs

to install a solenoid valve in the liquid line (not part of the standard delivery). In addition to the liquid

line solenoid valve a digital input signal from a room thermostat or a case temperature sensor must

S

afet

y

inst

ru

ctio

n

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e &

repai

r

Cer

tif

ica

tion

&

a

p

p

ro

va

l

Dismant

ling

&

d

ispo

sa

l