Dynamic Flow Computers

SFC332L Manual

Data Entry

— 2-21

Date: 8/1/2019

S

T A T U S

I

N P U T

/ S

W I T C H

O

U T P U T

A

S S I G N M E N T

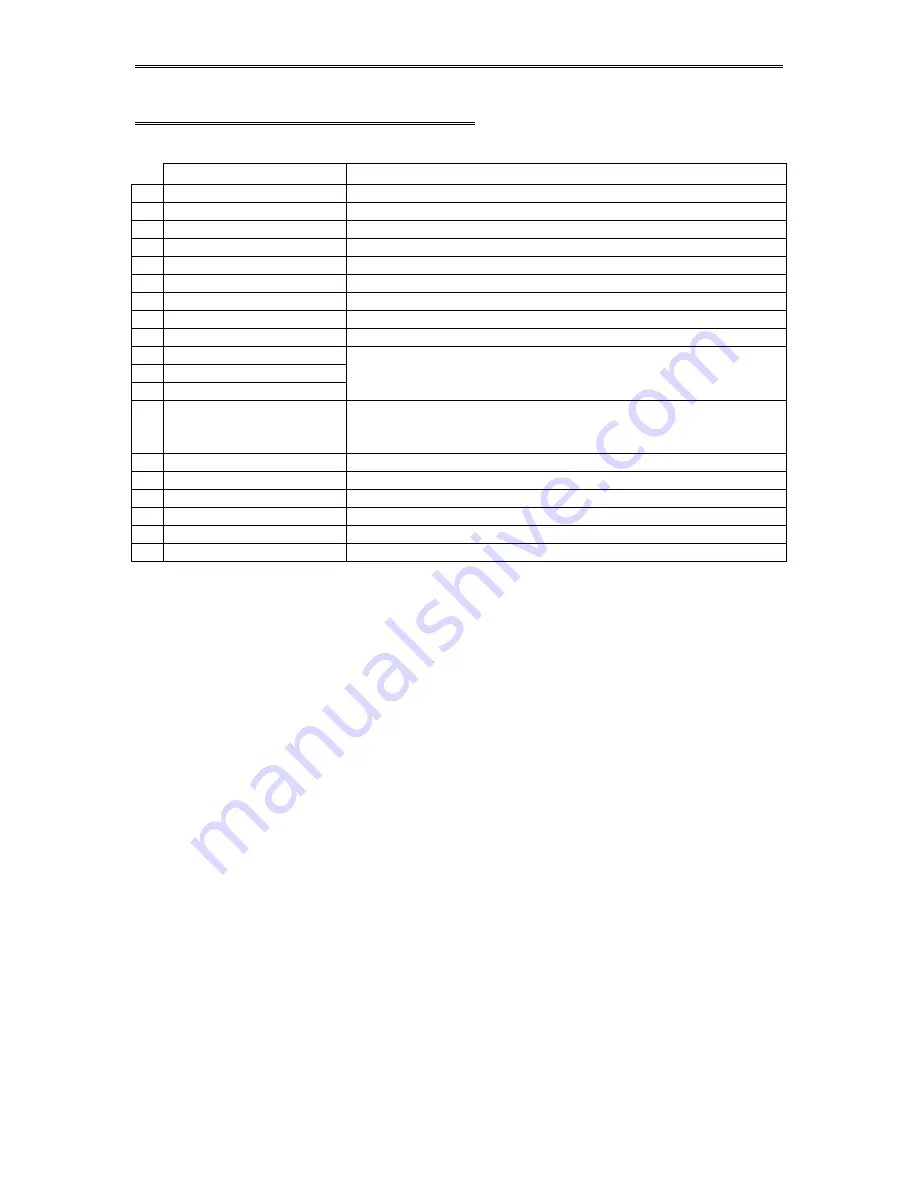

User can select any one of status input and assign it to input point.

Assignment

Comments

1

End Meter#1 Batch

End the batch for Meter #1 and reset batch totalizer

2

End Meter#2 Batch

End the batch for Meter #2 and reset batch totalizer

3

End Meter#1/#2 Batch

End the batch for Meter#1 and #2; reset both batch totalizers

4

Alarm Acknowledge

Reset the previous occurred alarms output bit

5

Flow Direction

“OFF”= forward and “ON”= reverse. For bi-directional meters

6

Display Freeze

Set to “ON” to halt scrolling and allow for continuous monitoring

7

Display Toggle

The display will scroll as the user toggles the status

8

N/A

9

Event Status

10

Product ID Bit 0

Product ID Bits: Before ending batch, user can use status bits to select

next product. These bits are read immediately at batch end.

See the following table to specify a product.

11

Product ID Bit 1

12

Product ID Bit 2

13

Print Request

Step 1: set port 2 Modbus type to 1 (printer type)

Step 2: When this status is activated, the Smart Flow Computer will

send the “Request Report” to the printer via the serial port #2.

14

Calibration Mode

15

Meter#2 Flow Direction

16

Status Counter#1

Reset at the end of batch

17

Status Counter#2

Reset at the end of batch

18

Status Counter#3

Reset at the end of batch

19

Status Counter#3

Reset at the end of batch

Summary of Contents for SFC332L

Page 15: ...Dynamic Flow Computers SFC332L Manual Quick Start 1 10 Date 8 1 2019 Memory Jumper ...

Page 17: ...Dynamic Flow Computers SFC332L Manual Quick Start 1 12 Date 8 1 2019 ...

Page 18: ...Dynamic Flow Computers SFC332L Manual Quick Start 1 13 Date 8 1 2019 ...

Page 26: ...Dynamic Flow Computers SFC332L Manual Quick Start 1 21 Date 8 1 2019 TURBINE SINE WAVE ...

Page 35: ...Dynamic Flow Computers SFC332L Manual Quick Start 1 30 Date 8 1 2019 ...