Programming

Operating Instructions 911-210-10 - 00.0 - 06/2020

75

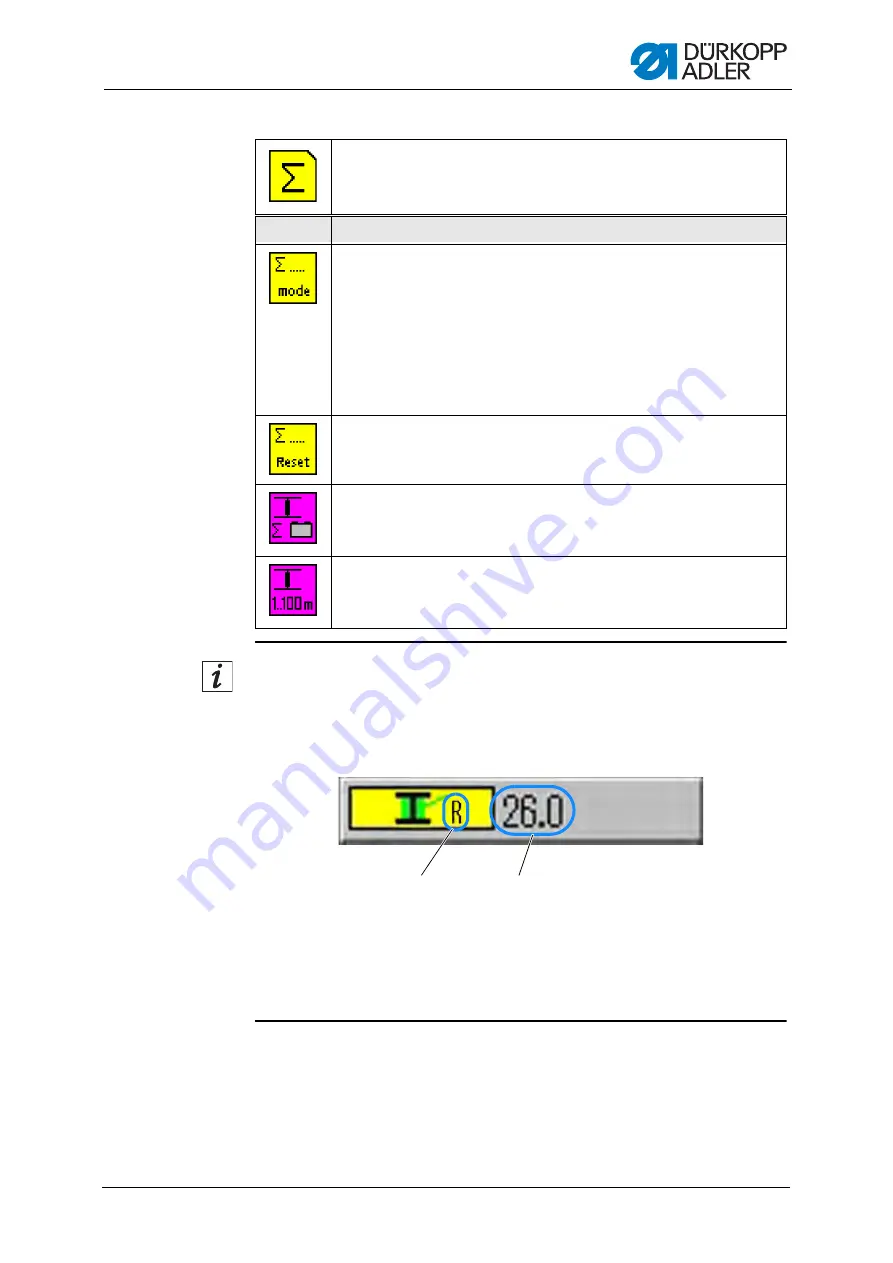

Information

The remaining thread monitor (MP 1,

Optionale Einrichtungen (Optional

equipment)

) and the bobbin counter (MP 6) can be activated simultane-

ously. The display shows the two options as follows:

Fig. 48: Remaining thread monitor and bobbin counter

MP6 - Counters

Symbol

Meaning

Counter type

The following options are available:

•

Increment counter

(Def.): The counter is incremented after each sewn

program

•

Decrement counter

: The counter is decremented after each sewn

program

•

Increment seam sequence counter:

The counter is incremented after

each seam sequence sewn

•

Decrement seam sequence counter:

The counter is decremented after

each seam sequence sewn

Reset value for the counter

(min. = 0 .. max. 9999; Def. 0)

Value to which the counter is set when a counter reset is performed

Set seam count for bobbin reserve

(min. = 0 .. max. 100; Def. 0)

A message is displayed to the user after the number of seams specified

here have been sewn. A value of 0 deactivates the function

Bobbin supply capacity

(min. = 0.0 .. max. 400.0; Def. 0.0 m)

A message is displayed to the user after the bobbin supply capacity has

been consumed. A value of 0 deactivates the function

(1)

- Display - remaining thread monitor:

Remaining thread monitor active:

R

shown

Remaining thread monitor inactive:

R

hidden

(2)

- Display - bobbin counter:

Bobbin counter active: Number black

Bobbin counter inactive:

Number grayed-out

①

②

Summary of Contents for 911-210-3020-10

Page 1: ...911 210 10 Operating Instructions...

Page 6: ...Table of Contents 4 Operating Instructions 911 210 10 00 0 06 2020...

Page 10: ...About these instructions 8 Operating Instructions 911 210 10 00 0 06 2020...

Page 18: ...Machine description 16 Operating Instructions 911 210 10 00 0 06 2020...

Page 34: ...Operation 32 Operating Instructions 911 210 10 00 0 06 2020...

Page 112: ...Setup 110 Operating Instructions 911 210 10 00 0 06 2020...

Page 114: ...Decommissioning 112 Operating Instructions 911 210 10 00 0 06 2020...

Page 116: ...Disposal 114 Operating Instructions 911 210 10 00 0 06 2020...

Page 124: ...Troubleshooting 122 Operating Instructions 911 210 10 00 0 06 2020...

Page 127: ......