96

DBC 130II

DBC130II ISE41

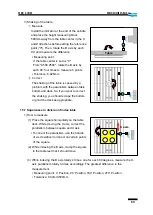

16.2 Resetting the reference point for the X axis (X-axis stroke: 3000mm)

1) Return the X axis to the reference point

manually.

2) In MDI mode, move the X axis to the middle

stroke position (X1500).

3) Install the test bar into the spindle and move

the W axis to "W0.".

4) Install the indicator in the center of the table

about 400mm high. In Handle mode, move the

Z axis in "-" direction so that it is positioned

about 30mm from the end of the test bar.

5) Move the indicator on the table deck so that the

gauge needle contacts on the test bar.

6) Move the Y axis and stop moving it when the

needle is positioned at the highest point of the

test bar. (Do NEVER move the X axis.)

7) Rotate the spindle and stop rotating it at the

intermediate point of the test bar runout. Then,

set the gauge to 0.

8) Move the Z axis in "+" direction by 400mm, and

rotate the B axis by 180 degrees.

9) Move the Z axis back in "-" direction and stop

right before the test bar contacts on the

indicator. Check if there occurs an interference

between indicator needle and end section of

the test bar. And if so, move the X axis to work

it around. (If the error is ignorable by the

indicator or there occurs no interference, just

skip this step) Then, move the Z axis until it is

positioned about 30mm from the end of the

test bar.

180

˚

회전

Summary of Contents for DBC 130 II

Page 1: ...Installation Manual DBC 130Ⅱ Machine Tools ...

Page 2: ......

Page 7: ...5 DBC 130II DBC130II ISE41 Ref 2 Right View Ref 3 Top View ...

Page 9: ...7 DBC 130II DBC130II ISE41 Ref 6 Top view of machine to install semi splash guard on Optional ...

Page 10: ...8 DBC 130II DBC130II ISE41 Ref 7 Top view of machine to install APC on Optional ...

Page 12: ...10 DBC 130II DBC130II ISE41 60 Tool Magazine ...

Page 60: ...58 DBC 130II DBC130II ISE41 Z axis ...

Page 121: ...119 DBC 130II DBC130II ISE41 19 Installation Complete ...