76

DBC 130II

DBC130II ISE41

※

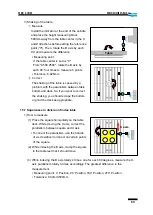

The above sample is the common instruction for reading the absolute value. As

straightness is a general concern when installing the boring machine, it is easier for you

to read only one-end gradation and compare five measuring points.

▪

In the table above, if the right side is 30μ higher, draw a right arrow and type in "30" in

the table. Repeat this for other two positions. From the three values, deduct the

smallest value from the largest, which will be the measurement.

②

The

measurement

may vary depending on your view position due to the distance

between gradation of the level and water bubble tube. So you must read the

gradation vertically at 90 degrees against the level.

8) If the level measurement falls below the target, perform the static accuracy inspection of

the machine before locking the anchor nut. If you find an error, use the level to correct

it. (refer to "static accuracy inspection and correction" below)

9) When the static accuracy of the machine falls

below the specified tolerance, tighten the

anchor nuts starting from the X axis. (The

leveling target above is the measurement after

the machine static accuracy inspection)

▪

To tighten the anchor nut

①

Tighten the already tightened level-block

adjusting bolt by another 1/4 turn

(approx. 90

˚) before locking the nut with

an appropriate torque. (starting from the

X axis)

②

Inspect the accuracy again and, if an error persists, use the level-block adjusting

bolt to correct the error.

※

If you tightened the bolts evenly at first, the error is not so great if any.

10) Repeat the steps above for the Z axis and tighten the anchor nut.

11) While measuring the levels of both X and Z axes again, tighten up the anchor nuts.

Summary of Contents for DBC 130 II

Page 1: ...Installation Manual DBC 130Ⅱ Machine Tools ...

Page 2: ......

Page 7: ...5 DBC 130II DBC130II ISE41 Ref 2 Right View Ref 3 Top View ...

Page 9: ...7 DBC 130II DBC130II ISE41 Ref 6 Top view of machine to install semi splash guard on Optional ...

Page 10: ...8 DBC 130II DBC130II ISE41 Ref 7 Top view of machine to install APC on Optional ...

Page 12: ...10 DBC 130II DBC130II ISE41 60 Tool Magazine ...

Page 60: ...58 DBC 130II DBC130II ISE41 Z axis ...

Page 121: ...119 DBC 130II DBC130II ISE41 19 Installation Complete ...