44

DBC 130II

DBC130II ISE41

6. Second Round of Grout Injection

※

When the temporary installation is completed, inject grout into the column bed, table bed

and the foundation holes of ATC base before curing the surface. This process is very

important because it affects the accuracy, strength and lifecycle of the machine and

more. For this reason, suitable grout materials and a correct, well-ordered workflow are

required for each process.

Uncertified grout and/or a faulty installation of the machine may cause serious problems

such as a delay and inaccurate precision work that may incur extra costs.

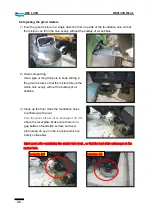

6.1 Checkpoints before injecting grout

1) Is the concrete surface of each foundation hole rough? (Chipping)

▪

If the foundation surface is smooth, then it is necessary to make it rough in order to

reinforce the adhesiveness between concrete wall that was constructed in the primary

foundation work, and secondary grout.

2) Has foreign matter inside of each foundation hole been completely removed?

▪

Rid the hole of any concrete debris or bits of flexible tubes used in making the

foundation hole.

3) Has each foundation hole been soaked in water?

▪

This is very important because it is to improve the adhesiveness and fluidity of grout

and to prevent it from drying too quickly. Fill the holes with water 12 hours before

grouting, and drain the water right before grouting.

6.2 Selection of Grout

High-quality grouting material contributes to seamless contact on the leveling block with

improved strength, forming a sound foundation for the machine.

1) Secondary grout requirements: 1.5

㎥

(3.6 tons)

120 sacks or so (Grout: 25 Kg)

2) Required compression strength of the secondary grout: 400 Kg/

㎠

or higher

3) Recommendation Grout

▪

Ssangyong Cement :

쌍용

바스콘

Plus

▪

Union : Grout GM

▪

Henkel : Ceresit CX11

Summary of Contents for DBC 130 II

Page 1: ...Installation Manual DBC 130Ⅱ Machine Tools ...

Page 2: ......

Page 7: ...5 DBC 130II DBC130II ISE41 Ref 2 Right View Ref 3 Top View ...

Page 9: ...7 DBC 130II DBC130II ISE41 Ref 6 Top view of machine to install semi splash guard on Optional ...

Page 10: ...8 DBC 130II DBC130II ISE41 Ref 7 Top view of machine to install APC on Optional ...

Page 12: ...10 DBC 130II DBC130II ISE41 60 Tool Magazine ...

Page 60: ...58 DBC 130II DBC130II ISE41 Z axis ...

Page 121: ...119 DBC 130II DBC130II ISE41 19 Installation Complete ...