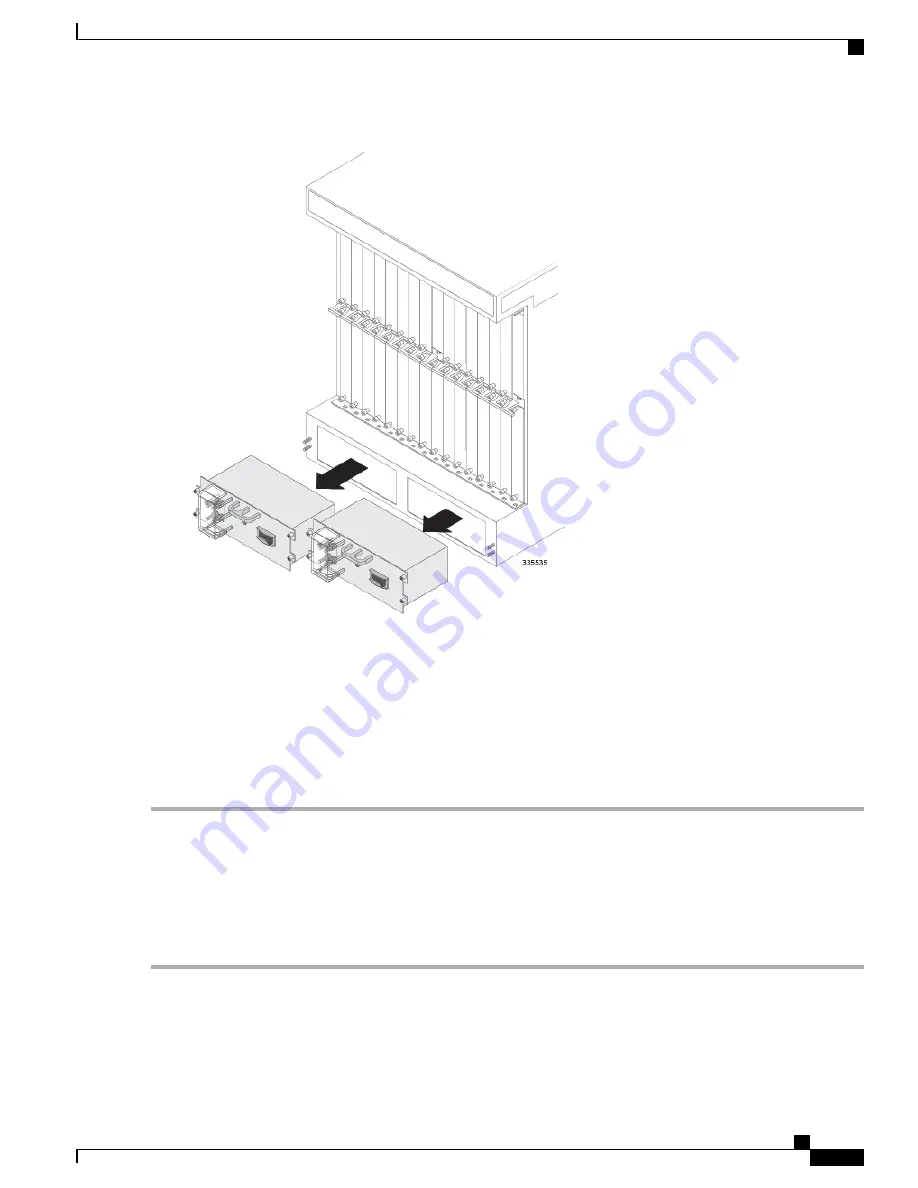

a) Locate the PFU bay labeled Power Filter Unit 1 on the lower-left rear of the chassis.

b) Use a Phillips #2 screwdriver to loosen the four screws that secure the PFU in to the chassis.

c) Grasp the handle on the PFU and gently pull the PFU toward you. The PFU should slide easily out of the chassis.

Place it to the side for re-installation later.

d) Repeat step b and step c for the PFU located in the bay labeled Power Filter Unit 2 located on the lower-right side

of the chassis.

Step 4

Proceed to either the

Flush Mount Installation of the Chassis, on page 57

or

Mid-Mount Installation of the Chassis, on

page 58

, based on the mounting option you are using.

Flush Mount Installation of the Chassis

Follow the instructions below to perform the flush mount installation of the chassis.

Step 1

Position the chassis in the equipment rack so that the flanges of the mounting brackets at the front of the chassis are flush

with the mounting rails of the equipment rack.

Step 2

Mount the chassis to the rails of the equipment rack. Use the hardware that was supplied with the equipment rack. Begin

with the two bottom holes and work your way up until all four holes on each flange are secured.

ASR 5000 Installation Guide

57

Chassis Installation

Flush Mount Installation of the Chassis

Summary of Contents for ASR 5000

Page 16: ...ASR 5000 Installation Guide xvi About this Guide Contacting Customer Support ...

Page 64: ...ASR 5000 Installation Guide 48 Installation Procedure Overview Laser Notice ...

Page 100: ...ASR 5000 Installation Guide 84 Line Card Installation Installing the XGLC ...

Page 122: ...ASR 5000 Installation Guide 106 Cabling the Fast Ethernet 10 100 Line Card FLC2 Interfaces ...

Page 206: ...ASR 5000 Installation Guide 190 Removing and Installing SMC PC Cards Removing PC Cards ...

Page 212: ...ASR 5000 Installation Guide 196 Replacing the Chassis Air Filter Installing the Air Filter ...

Page 220: ...ASR 5000 Installation Guide 204 Replacing a Power Filter Unit What to do with the Failed PFU ...

Page 266: ...ASR 5000 Installation Guide 250 Safety Electrical and EMC Certifications Korean EMC ...

Page 270: ...ASR 5000 Installation Guide 254 Environmental Specifications Chassis Air Flow ...