B-2

CP2210 Service Manual

020-100556-04 Rev. 1 (01-2012)

Appendix B: Overfill

5. Turn the screw 1/4” of a turn in the same direction.

NOTE:

Each turn must be exactly 1/4” of a turn to

ensure accuracy.

If there is no shadow at the top of the image turn the screw another 1/4” in the same

direction.

6. Although it is hard to see find the top edge of the DMD output, typically this is where the edge of the

screen is assuming the integrator is aligned.

7. Use a ruler to measure from the top edge of the DMD output to the point where there is no discoloration or

fading of the white image (

Figure B-2

). This will give you the centimeters that the output beam moved.

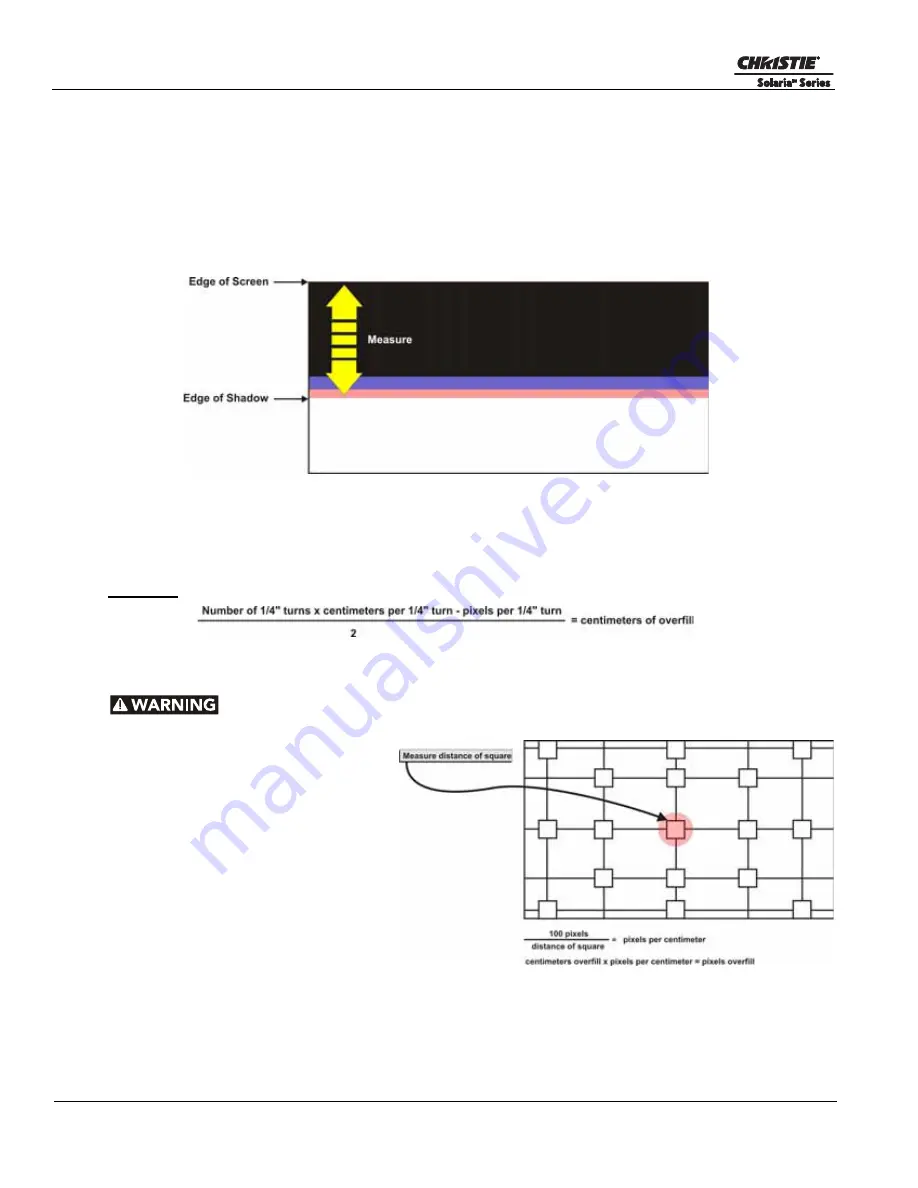

Figure B-2Adjusting Overfill

8. Subtract the pixels per 1/4” turn value (Step 7) from the number of pixels that the light beam traveled (Step

3) and dived by two. This will give you the centimeters of overfill on the top and bottom.

9. Repeat Steps 1-8 for the left and right overfill.

Equation:

B.1.2 Converting Centimeters to Pixels

Overfill should be adjusted to 15 pixels on each side.

1. Display a 17L-Point test pattern by

accessing the

Test Patterns

menu via

the TPC and selecting

DC2K 17L

Point

.

NOTE:

This test pattern is

included with DLP cinema releases

11.1.33 or higher.

2. Use a ruler to measure the width of a

square on the test pattern (

Figure B-

3

). This box is 100 pixels wide.

3. Repeat the entire procedure for

horizontal overfill. The travel per 1/4”

turn is different every time.

4. Once both vertical and horizontal

overfill is completed re-align the integrator and fold mirror. For details, refer to

3.3 Integrator Alignment,

on page 3-3

and

3.2 Fold Mirror Alignment, on page 3-2

.

Figure B-3 Test Pattern