HEATER A N D AIR C O N D IT IO N IN G

1A-19

Receiver-Dehydrator.......................................................1A-76

Sight G lass........................................................................1A-76

Blower-Evaporator Assembly...................................... .1A-76

Blower Assembly............................................................ .1A-77

Expansion Valve, Evaporator Case or Core..........1A-77

Thermostatic and/or Blower Switches.....................1A-78

Resistor...............................................................................1A-78

Fuse.....................................................................................1A-78

Diagnosis..............................................................................1A-78

Refrigerant System.........................................................1A-78

Compressor Diagnosis....................................................1A-80

Insufficient Cooling........................................................ 1A-81

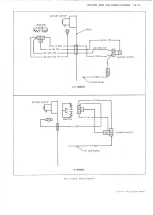

Electrical System Diagnosis........................................ .1A-83

Vacuum System Diagnosis.......................................... .1A-87

Special Tools.......................................................................1A-94

GENERAL DESCRIPTION

FOUR-SEASON SYSTEM (C-K MODELS)

Both the heating and cooling functions are performed by

this system. Air enterning the vehicle must pass through

the cooling unit (evaporator) and through (or around)

the heating unit, in that order, and the system is thus

referred to as a "reheat" system.

The evaporator provides maximum cooling of the air

passing through the core when the air conditioning

system is calling for cooling. A thermostatic switch,

located in the blower-evaporator case, acts to control

compressor operation by sensing the fin temperature of

the evaporator core.

System operation is as follows: Air, either outside air or

recirculated air, enters the system and is forced through

the system by the blower. As the air passes through the

evaporator core, it receives maximum cooling if the air

conditioning controls are calling for cooling. After

leaving the evaporator, the air enters the Heater and Air

Conditioner Selector Duct Assembly where, by means of

diverter doors, it is caused to pass through or to bypass

the heater core in the proportions necessary to provide

the desired outlet temperature. Conditioned air then

enters the vehicle through either the floor distributor

duct or the dash outlets. When, during cooling

operations, the air is cooled by the evaporator to below

comfort level, it is then warmed by the heater to the

desired temperature. During "heating only" operations,

the evaporator will not be in operation and ambient air

will be warmed to the desired level in the same manner.

The dash outlets are rectangular in design. The outlets

can be rotated horizontally or vertically to direct air as

desired. Under the left distributor duct is located a floor

cooler which can be rotated to provide cooling air or shut

off completely.

FLOOR MOUNTED SYSTEM (G MODELS)

This system (C62) performs the cooling functions only.

When heating (above ambient temperatures) is desired,

the standard equipment heater must be used. When air

conditioning is desired, be sure the heater is completely

shut off.

This self contained unit (fig. 22), operates on recirculated

inside air only. Recirculated air is drawn into the unit,

passes through the evaporator core (receiving maximum

cooling) and then directed into the vehicle through

adjustable outlets located in the ducts.

A thermostatic switch, located on the evaporator cover, is

used to control compressor operation by sensing air

temperature as it leaves the evaporator core.

OVERHEAD SYSTEMS (C-K-G MODELS)

These systems (C69 on C-K Models, C63 on G Models)

operate in conjunction with the Four-Season System (C-

K Models) or Floor Mounted System (G Models)-they

do not operate independently.

NOTE: Overhead system kits are available

for non-factory installation on C-K Models,

providing the vehicle is equipped with the

front system.

Like the floor-mounted system, these units are self

contained, operating on inside (recirculated) air only. Air

is drawn into the unit, passed through the evaporator

core and then directed into the passenger compartment

through adjustable outlets in the air distributor duct.

System control is through the thermostatic switch in the

front system. The only control on the overhead system is

a three speed blower switch.

MOTOR HOME CHASSIS SYSTEM

This system performs the cooling functions only. When

Fig. 22--C62 Interior Components (G Models)

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......