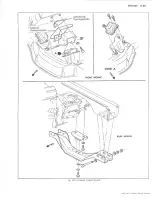

6 K - 4 E N G IN E C O O L IN G

WARM WATER

FROM ENGINE

COLD RADIATOR TRANSMISSION

FILL LEVEL

OIL COOLER

LINES

RADIATOR CODE'

LOCATION

COOLED WATER

TO ENGINE

Fig. 5—Typical Cross-Flow Radiator

held against its seat by a spring, which, when

compressed, allows excessive pressure to be relieved out

the radiator overflow. The vacuum valve is also held

against its seat by a spring which, when compressed,

opens the valve to relieve the vacuum created when the

system cools.

Fan

The cooling fan is located on the end of the water pump

shaft and is driven by the same belt that drives the

pump. In some instances a fan shroud surrounds the fan.

This shroud increases the cooling system efficiency by

ensuring that all air pulled in by the fan passes through

the radiator. Basically there are two types of fans: a fixed

drive fan (which rotates at water pump - engine rpm -

speed) and the automatic fan clutch.

Automatic fan clutches, Figure 6, are hydraulic devices

used to vary the speed in relation to the engine

temperature. Automatic fan clutches are used with many

engines, especially those equipped with factory installed

air conditioning units. Automatic fan clutches permit the

use of a high delivery fan to insure adequate cooling at

reduced engine speeds while eliminating overcooling,

excessive noise, and power loss at high speeds.

The automatic fan clutch has two modes of operation,

the engaged mode and the disengaged mode. The

disengaged mode (engine cold or high speed driving)

occurs when the silicone fluid is contained in the

reservoir area of the fan clutch. As the temperature of

the engine rises so does the temperature of the bimetallic

coil. This bimetallic coil is connected to the arm shaft in

such a way that as the temperature rises the shaft moves

the arm exposing an opening in the pump plate. This

opening allows the silicone fluid to flow from the

reservoir into the working chamber of the automatic fan

clutch.

The silicone fluid is kept circulating through the fan

clutch by wipers located on the pump plate. A hole is

located in front of each wiper, Figure 7. The speed

differential between the clutch plate and the pump plate

develops high pressure areas in front of the wipers, thus

the fluid is forced back into the reservoir. But as the

temperature rises the arm uncovers more of the large

opening and allows more of the silicone fluid to re-enter

the working chamber.

The automatic fan clutch becomes fully engaged when

the silicone fluid, circulating between the working

chamber and the reservoir, reaches a sufficient level in

the working chamber to completely fill the grooves in the

clutch body and clutch plate.

The resistance of the silicone fluid to the shearing action

caused by the speed differential between the grooves

transmits torque to the clutch body. The reverse situation

occurs when the temperature drops. The arm slowly

closes off the return hole thus blocking the fluid flow

from the reservoir into the working chamber.

The continuous action of the wipers removes the silicone

fluid from the grooves in the working chamber and

reduces the shearing action. Thus, less torque is

transmitted to the clutch body and the speed of the fan

decreases.

The temperature at which the automatic fan clutch

engages and disengages is controlled by the setting of

the bimetallic coil. This setting is tailored to satisfy the

cooling requirements of each model.

FAN CLUTCH DIAGNOSTIC

PROCEDURE

1.

NOISE

Fan noise is sometimes evident under the following

normal conditions: a. when clutch is engaged for

maximum cooling, and b. during first few minutes after

start-up until the clutch can re-distribute the silicone

fluid back to its normal disengaged operating condition

after overnight settling.

However, fan noise or an excessive roar will generally

occur continuously under all high engine speed

conditions (2500 r.p.m. and up) if the clutch assembly is

locked up due to an internal failure. If the fan cannot be

roated by hand or there is a rough grating feel as the

fan is turned, the clutch should be replaced.

2.

LOOSENESS

Under various temperature conditions, there is a visible

lateral movement that can be observed at the tip of the

fan blade. This is a normal condition due to the type of

bearing used. Approximately 1/4" maximum lateral

movement measured at the fan tip is allowable. This is

not cause for replacement.

3.

SILICONE FLUID LEAK

The operation of the unit is generally not affected by

small fluid leaks which may occur in the area around the

bearing assembly. However, if the degree of leakage

appears excessive, proceed to item 4.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......