Chapter 5 – Parameter List

4-9

Keypad-1. The frequency in DRV-00 parameter is the 1

st

Speed and the 2

nd

Speed is activated by M1 input

and can be adjusted in parameter DRV-01.

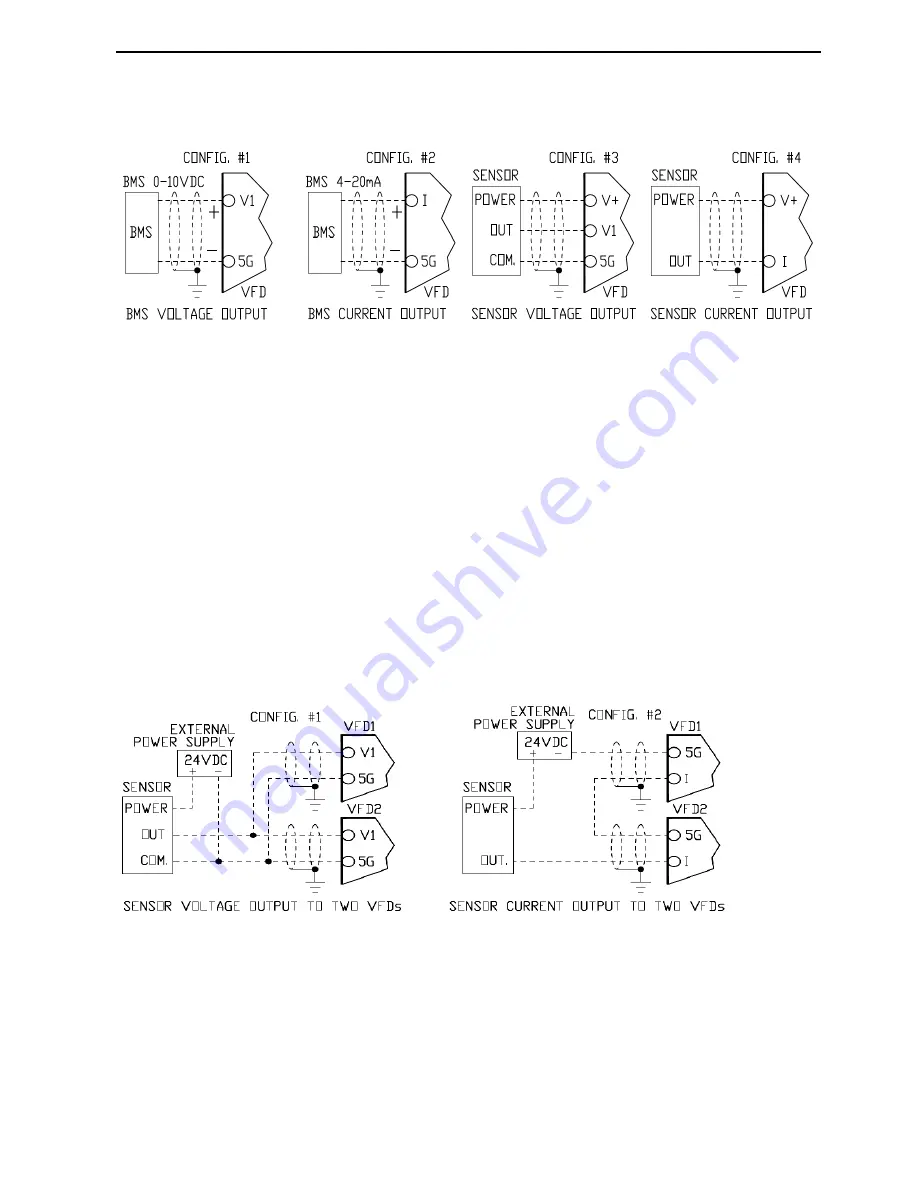

4.4.2 Examples of analog speed control configurations

The 4.4.2 picture shows four most common VFD speed control configurations.

Config. #1

shows VFD with speed controlled by remote 0-10VDC signal from BMS, PLC or any other

controller. The VFD parameter SET-10 is set to V1 mode. During normal operation if an electrical noise

level in analog signal is too high, VFD output can stay at maximum frequency for some time when speed

reference signal is decreasing. Increase a filtering time setting in parameter I/O-01 up to 500mS.

Config. #2

shows VFD with speed controlled by remote 4-20mA signal from BMS, PLC or any other

controller. The VFD parameter SET-10 is set to I mode. During normal operation if a noise level in analog

signal is too high, VFD output can stay at maximum frequency for some time when speed reference signal is

decreasing. Increase a filtering time setting in parameter I/O-06 up to 500mS.

Config. #3

shows VFD with automatic speed control by internal PID and 0-10VDC feedback signal from

pressure, temperature or any other transducer. The VFD PID parameter SET-20 is enabled and SET-21 is set

to V1 mode. Increasing a filtering time setting in parameter I/O-01, when PID control is enabled, can

decrease a control accuracy.

Config. #4

shows VFD with automatic speed control by internal PID and 4-20mA feedback signal from

pressure, temperature or any other transducer. The VFD PID parameter SET-20 is enabled and SET-21 is set

to I mode. Increasing a filtering time setting in parameter I/O-06, when PID control is enabled, can decrease

a control accuracy.

Two VFDs wired to one transducer.

Config. #1

above shows two VFDs with automatic speed controls by internal PIDs and 0-10VDC feedback

signal from one pressure, temperature or any other transducer with external 24VDC power source. The

sensor with 0-10VDC output can be paralleled with multiple VFDs. Losing the power on one VFD does not

affect the PID operation of another VFD with transducer feedback. Use CM instead of 5G for VFDs 50HP

and above.

Config. #2

above shows two VFDs with automatic speed controls by internal PIDs and 4-20mA feedback

signal from one pressure, temperature or any other transducer with external 24VDC power source. The

sensor with 4-20mA output is usually limited by 650 load impedance. The VFD input impedance is 249

thus only two VFDs can be connected in series with one transducer. Losing the power on one VFD does not

affect the PID operation of another VFD with transducer feedback. Use CM instead of 5G for VFDs 50HP

and above.

Summary of Contents for CI-007-P2

Page 23: ......

Page 107: ......

Page 110: ...Chapter 6 Parameter Description 7 4 PID control with Pipe Broken function diagram...

Page 111: ...Chapter 6 Parameter Description 7 4 7 5 PID control with Pre PID function diagram...

Page 112: ...Chapter 6 Parameter Description 7 5 7 6 PID Control Setting Notes...

Page 113: ......