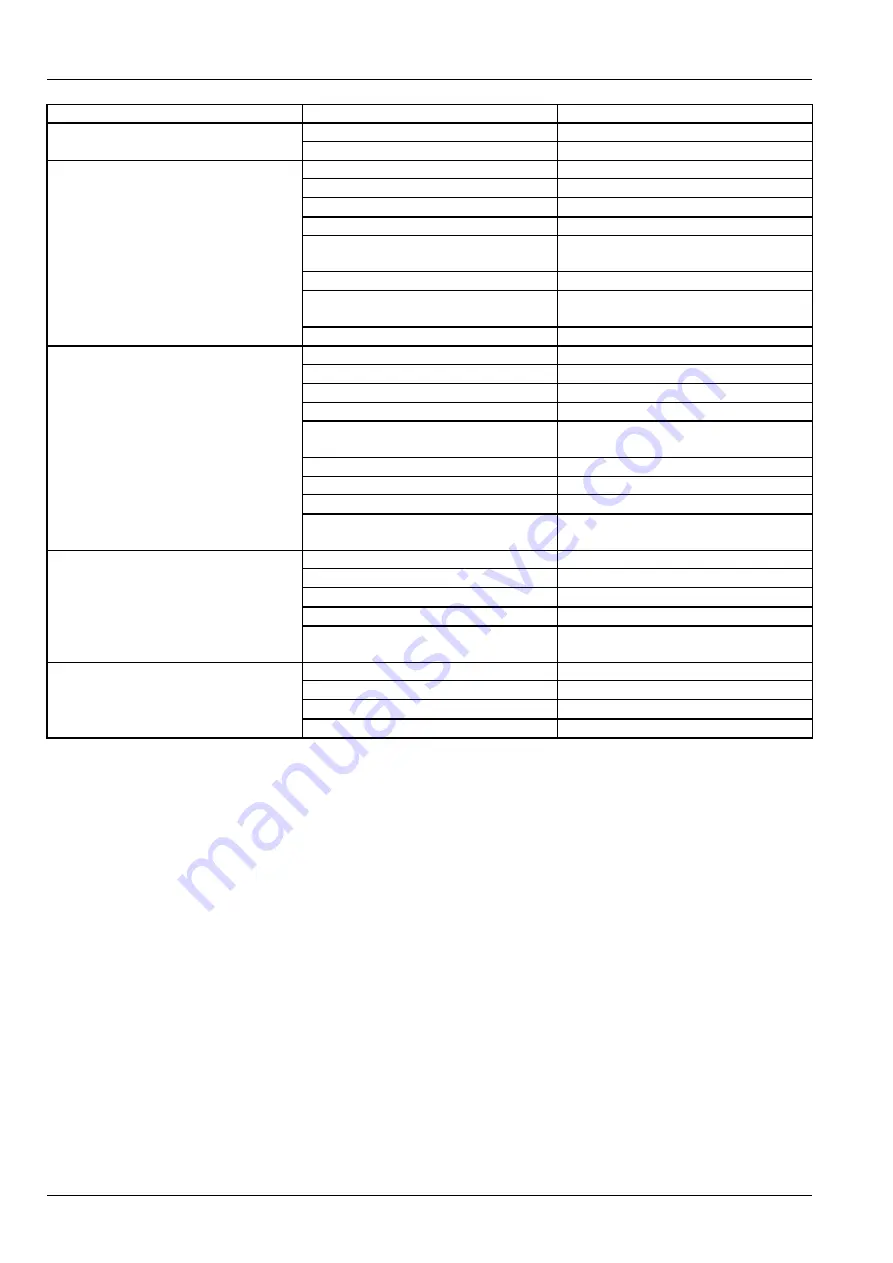

8 - TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

CORRECTION

Incorrect installation.

Correct the installation.

No differential action; jamming while

steering.

Bent or broken axle shaft.

Replace the axle beam.

Incorrect installation.

Correct the installation.

Defective axle.

Inspect and repair.

Wrong weight distribution.

Distribute the weight differently.

Overload.

Remove the excessive load.

Incorrect tyre rotation radius.

Replace the tyre or adjust pressure

on both tyres.

Bent or broken axle shaft.

Replace the axle beam.

Incorrect wheel alignment.

Check that the structure and the

bearings are in good conditions.

Excessive noise.

Incorrect axle part installation.

Check the installation.

Incorrect installation.

Correct the installation.

Defective axle.

Inspect and repair.

Wrong weight distribution.

Distribute the weight differently.

Overload.

Remove the excessive load.

Incorrect tyre rotation radius.

Replace the tyre or adjust pressure

on both tyres.

Bent or broken axle shaft.

Replace the axle beam.

Blocked differential.

Check the installation.

Excessive steering angle.

Reduce the steering angle.

Excessive wear of the tyre.

Incorrect wheel alignment.

Check that the structure and the

bearings are in good conditions.

Incorrect installation.

Correct the installation.

Bent or broken axle shaft.

Replace the axle beam.

Damaged or worn axle parts.

Replace the damaged axle parts.

Incorrect axle part installation.

Check the installation.

Friction noise.

Incorrect adjustment of the bevel

gear set.

Adjust the bevel gear set.

Incorrect installation.

Correct the installation.

Defective axle.

Inspect and repair.

Wrong weight distribution.

Distribute the weight differently.

Vibrations during travel.

Bent or broken axle shaft.

Replace the axle beam.

8-14

Summary of Contents for 580ST

Page 8: ......

Page 24: ...1 GENERAL INFORMATION 1 16 ...

Page 49: ...2 SAFETY INFORMATION Extend telescopic dipper If fitted MOLI12LBB0092AA 24 2 25 ...

Page 101: ...3 CONTROLS AND INSTRUMENTS Setup menu LEIL12TLB00006I 1 3 39 ...

Page 144: ...3 CONTROLS AND INSTRUMENTS 3 82 ...

Page 164: ...4 OPERATING INSTRUCTIONS 4 20 ...

Page 166: ...5 TRANSPORT OPERATIONS RAIL14TLB1181GA 1 5 2 ...

Page 222: ...6 WORKING OPERATIONS 6 44 ...

Page 247: ...7 MAINTENANCE Fuel tank capacity 145 L 38 30 US gal 2WS 124 L 32 76 US gal 4WS 7 25 ...

Page 347: ...7 MAINTENANCE Fuses and relays Powershift cab 2WS MOLI12LBB0491CA 7 7 125 ...

Page 349: ...7 MAINTENANCE Fuses and relays Powershift cab 4WS MOLI12LBB0492CA 8 7 127 ...

Page 390: ...8 TROUBLESHOOTING 8 28 ...

Page 418: ...9 SPECIFICATIONS 4WS LEEN11T0039FA 2 9 28 ...

Page 420: ...9 SPECIFICATIONS 2WS 590ST LEEN11T0041FA 5 4WS 695ST LEEN11T0042FA 6 9 30 ...

Page 433: ......