2003 Buell XB9R: Chassis

2-29

HOME

CLEANING AND INSPECTION

1

1

WARNING

1

WARNING

Clean brake system components using denatured alco-

hol. Do not use mineral-base cleaning solvents, such as

gasoline or paint thinner. Use of mineral-base solvents

causes deterioration of rubber parts that continues after

assembly. This may result in improper brake operation

which could result in death or serious injury.

1.

Clean all parts with denatured alcohol or D.O.T. 4

BRAKE FLUID. Do not contaminate with mineral oil or

other solvents. Wipe dry with a clean, lint free cloth. Blow

out drilled passages and bore with a clean air supply. Do

not use a wire or similar instrument to clean drilled pas-

sages.

2.

Carefully inspect all components. Replace any parts that

appear damaged or worn. Do not hone caliper piston

bore.

1

1

WARNING

1

WARNING

Always replace brake pads in complete sets for correct

brake operation. Never replace just one brake pad. Fail-

ure to install brake pads as a set could result in death or

serious injury.

3.

Inspect brake rotor and pads. See

1.6 BRAKE SYSTEM

MAINTENANCE

.

4.

Check rotor surface. Replace if warped or badly scored.

See

Table 2-10.

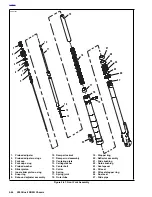

ASSEMBLY

1.

See

Figure 2-42.

Install pistons and o-rings.

a. Lubricate

new o-rings (6), pistons (5), and caliper

piston bores with D.O.T. 4 BRAKE FLUID.

b. Install two new o-rings (6) in grooves of each piston

bore.

c.

Install pistons (5) in each piston bore.

2.

Install new o-rings (8) between caliper halves.

3.

Clamp caliper together with caliper fasteners (11) and

tighten to 15-19 ft-lbs (20-26 Nm).

INSTALLATION

1.

See

Figure 2-42.

Install brake pads (10).

2.

Install pin hanger set (1) and tighten to 11-14 ft-lbs (15-

19 Nm).

3.

Rotate front fork counterclockwise and install caliper on

caliper mount. Using LOCTITE 272, tighten fasteners (9)

to 35-37 ft-lbs (47-50 Nm).

4.

Rotate front fork/caliper clockwise and slide caliper onto

rotor.

1

1

WARNING

1

WARNING

Use only copper crush banjo washers (See Parts Catalog

for Part No.) with D.O.T. 4 brake fluid. Earlier silver banjo

washers are not compatible with D.O.T. 4 fluid and will

not seal properly over time. Failure to comply may

adversely affect braking ability and lead to brake failure

which could result in death or serious injury.

5.

Install brake line to caliper. See

2.11 FRONT BRAKE

LINE

.

6.

Bleed front brakes. See

BLEEDING BRAKES

in

1.6

BRAKE SYSTEM MAINTENANCE

.

1

1

WARNING

1

WARNING

Check for proper brake lamp operation before riding

motorcycle. Visibility is a major concern for motorcy-

clists. Failure to have proper brake lamp operation could

result in death or serious injury.

7.

Turn ignition key switch to ON. Apply brake hand lever to

test brake lamp operation.

Table 2-10. Front Rotor Runout

RUNOUT

IN.

MM

Radial

0.0177

0.45

Lateral

0.0248

0.63

Summary of Contents for XB9R 2003

Page 2: ...1 2 Edit Me Printed June 5 2002 12 26 pm ...

Page 35: ...D 2 2003 Buell XB9R Appendix D HOME Figure D 2 Rear Brake Systems Top View b1115xbx ...

Page 36: ...2003 Buell XB9R Appendix D D 3 HOME Figure D 3 Rear Brake Systems Left Side View b1116xcx ...

Page 47: ...D 14 2003 Buell XB9R Appendix D HOME NOTES ...

Page 49: ......

Page 77: ...1 28 2003 Buell XB9R Maintenance HOME NOTES ...

Page 103: ...1 54 2003 Buell XB9R Maintenance HOME NOTES ...

Page 105: ... 2 ...

Page 191: ......

Page 263: ...3 72 2003 Buell XB9R Engine HOME NOTES ...

Page 299: ...4 2 2003 Buell XB9R Fuel System HOME NOTES ...

Page 385: ...4 88 2003 Buell XB9R Fuel System HOME NOTES ...

Page 421: ...4 124 2003 Buell XB9R Fuel System HOME NOTES ...

Page 423: ......

Page 445: ...5 22 2003 Buell XB9R Starter HOME NOTES ...

Page 447: ......

Page 469: ...6 22 2003 Buell XB9R Drive Transmission HOME NOTES ...

Page 497: ...6 50 2003 Buell XB9R Drive Transmission HOME NOTES ...

Page 499: ......