70

Bosch Rexroth AG

| Tightening Technology

3 608 878 300

System 350

| 3 608 878 300/2019-03

4.2.2.2

GripLine

The GripLine hand-held nutrunner is technically identical to the SlimLine model. However, the GripLine

angle head is equipped with an ergonomic plastic coating additionally. This way, the handling is improved

and scratches to the workpiece are avoided. A protective device prevents textiles and other things from

being caught.

4.2.2.3

VarioLine

The VarioLine hand-held nutrunner is suitable for special applications. The model consists only of a

standard machine. An output drive is selected for the corresponding application. With this machine, the

parameters of the output drive (efficiency, transmission ratio) can be entered in the BS350 operating

system and stored in the hand-held nutrunner. The VarioLine hand-held nutrunner can also be used as a

tightening spindle.

VarioLine with attached open flat output drive

For tightening operations at brake lines, for example, a hand-held nutrunner with attached open flat output

drive may be used. The open flat output drive is configured in the tightening channel configuration. See

Channel configuration of open flat output drives

.

4.2.2.4

ESM pistol grip nutrunner

The ESM pistol grip nutrunner is technically very similar to the SlimLine hand-held nutrunner. However,

the housing has a pistol shape. This allows for safe operation, even in confined areas. The nutrunner only

consists of the standard machine. It is equipped with a configurable tightening position illumination.

The output drive interface in SD models is square; in QD models it is a quick-change chuck for simple

assembly and disassembly of the tool. The HT models are equipped with a square plus Hirth toothing.

This allows to flange a planetary gearbox, thus enabling high tightening torques.

4.2.3

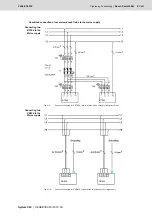

Connection cables

Thanks to the single-cable solution between tightening spindle or ErgoSpin hand-held nutrunner and the

controller, the number of necessary cables is low. The fully digital data communication ensures

interference-free transfer and reliable measurement values.

All newer models of connection cables for tightening spindle and ErgoSpin hand-held nutrunner have

sealed plug-in connectors.

CAUTION

Danger of injury due to high voltage and loss of functional and system

reliability!

The residual-current-operated protective device may trigger if the cables between tightening spindle

and CS351 compact system are too long! Danger to the functional and system reliability of the

tightening system!

In connection with the compact system CS351, use cables with a maximum length of 50 meters.

Note:

The length of the connection cable for certain components may be limited. You must

therefore observe the length specification if stickers with limitations are attached to the

components.

In connection with the servo amplifiers in the modular system, use cables with a maximum length

of 100 meters.

As extension, do not connect more than 5 extension cables in line to the connecting cable.

Lay the cables in a way that no one will trip over them.

Observe the minimum bending radius of connection cables.

Summary of Contents for Rexroth Tightening System 350

Page 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Page 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...