3 608 878 300

Tightening Technology |

Bosch Rexroth AG 293

System 350

| 3 608 878 300/2019-03

The ID code is transferred into the tightening process once the tightening cycle has started (

CH x.y CW,

CH x.y CCW

). The tightening system evaluates the stipulated area for ID-codes (max. 64 characters in

CS351) from the data buffer. Irrelevant characters in the stipulated buffer area must be filled with spaces.

Field bus interface in the communication unit

ID-code assignment is implemented by dividing the data input field (see below).

The ID code must be stored in the data input field 100 ms before starting the tightening (

CH x.y CW,

CH x.y CCW

or

FO x CW, FO x CCW

) and remain stored until the end of tightening (

CH x.y CyCmp

,

FO

x CyCmp

) so that it can be used in the next tightening process.

The ID code is applied to the tightening process once the tightening cycle has started (start of tightening

application

FO x Cw, FO x CCW

, or start of tightening channel

Ch x.y Cw, CH x.y CCW

). The tightening

system evaluates the stipulated area for the ID-code for the respective application or tightening channel

in the data buffer (max. 64 characters). Irrelevant characters in the stipulated buffer area must be filled

with spaces.

Division of the data

input field

The division of the data input field determines which characters (bytes) from this data field will be used

for which ID code (application/single-channel tightening). This division is implemented in the BS350

operating program at

KE field bus

data

. This function is available online (with the configuration of the

connected controller) or offline (with a communication unit configuration stored on the hard drive). The

configuration of the communication unit is necessary to determine the available data fields for inputs and

outputs. To open the function, go to

System

KE field bus data

(online) or

File

New

KE field bus

data

(offline).

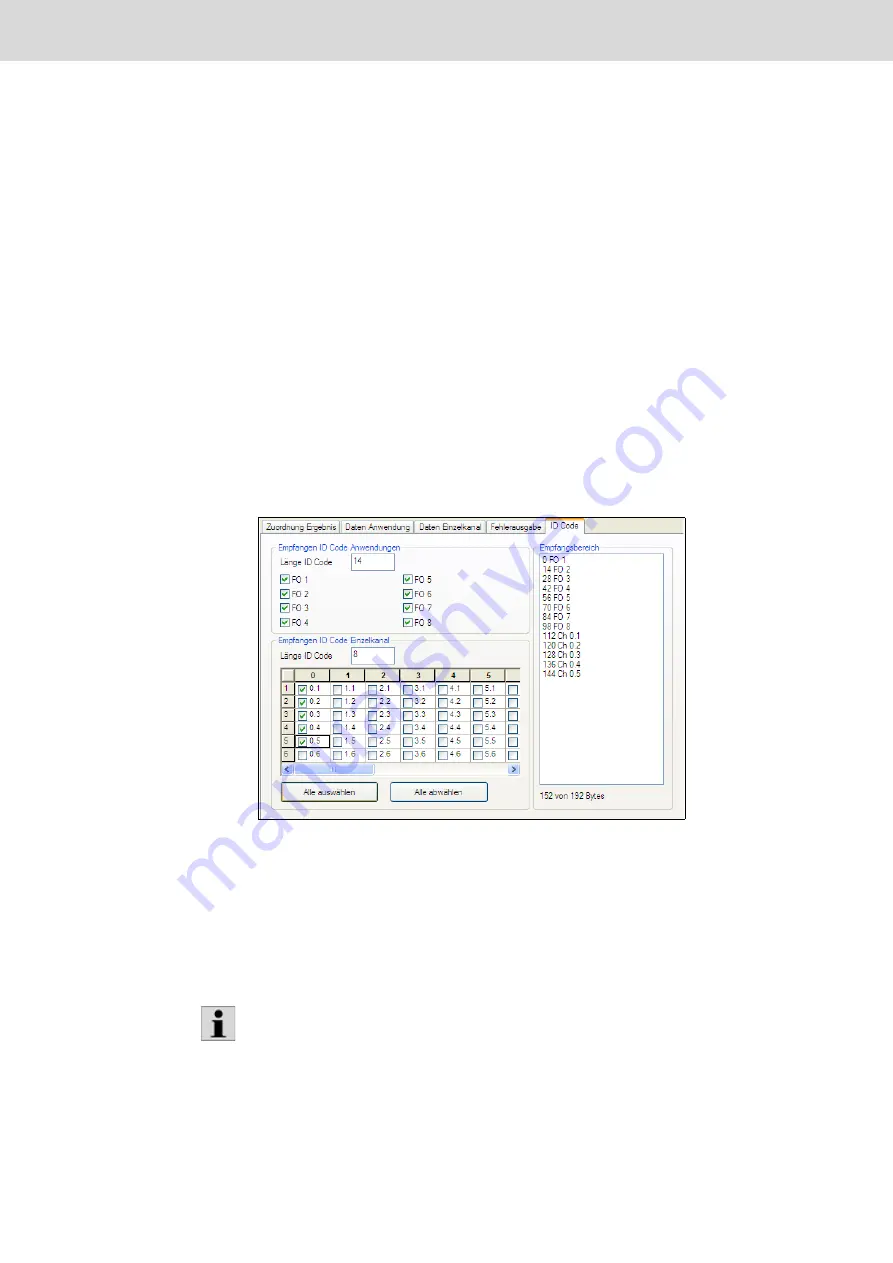

Fig. 6–49:

Determining ID code positions and sizes in the receipt range

In Figure

, the default setting of 14 bytes was kept as the length for ID codes for applications; 8

bytes were set for the ID codes for single-channel tightenings.

ID codes should be transmitted for all application blocks (FO1 to FO8) and for the single channels 0.1 to

0.5 (the communication unit is inserted into slot 0.6).

The start address in the data input field is listed in the right section of the window for each entry, as well

as the total number of bytes used with information on the maximum size (here 152 of 192 bytes) set by

the interface module configuration (in the KE configuration).

As the list shows, the tightening system expects the ID codes at the stipulated memory positions in the

data input field. The field bus master must provide the required strings (ASCII) at these memory positions.

Summary of Contents for Rexroth Tightening System 350

Page 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Page 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...