Learning Advanced Features

138

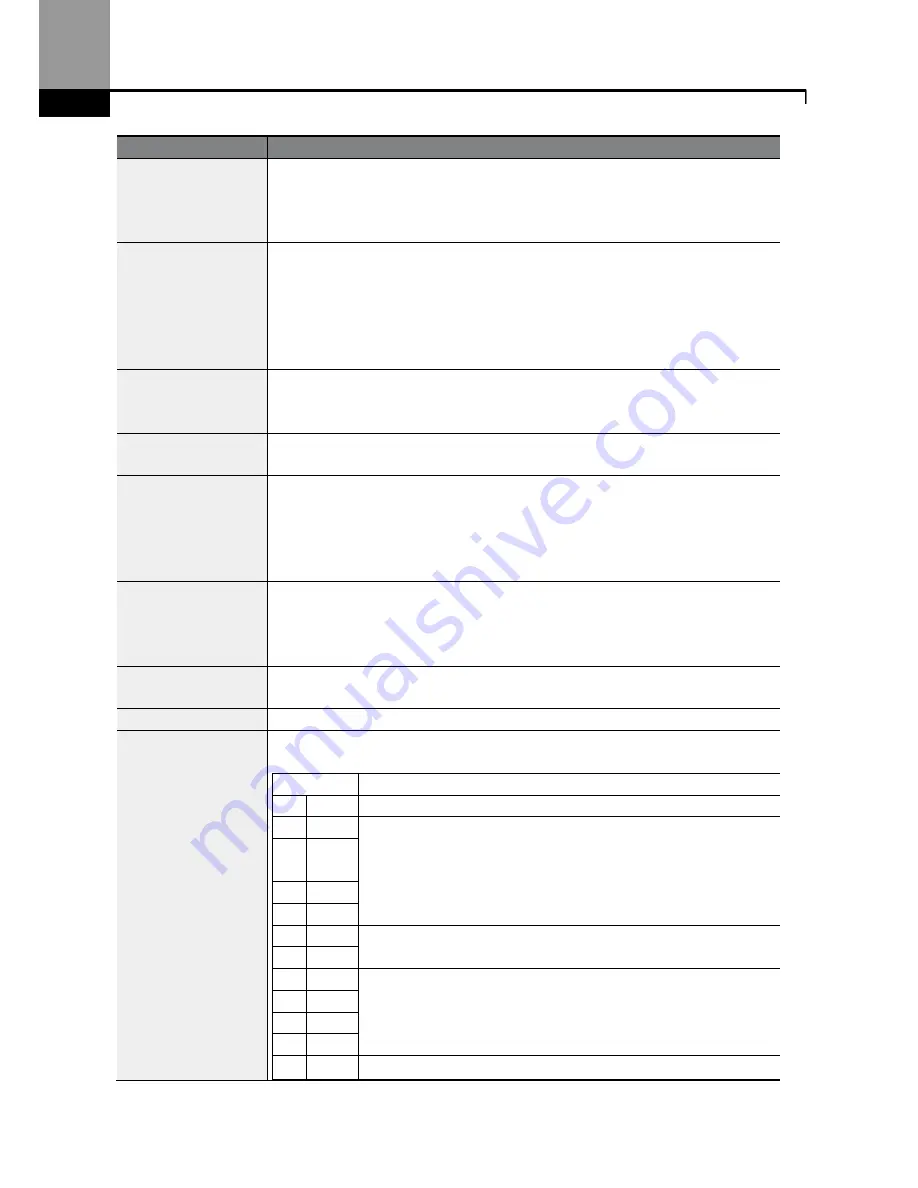

Code

Description

AP.22 PID P-Gain,

AP.26 P Gain Scale

Sets the output ratio for differences (errors) between reference (setpoint)

and feedback. If the Pgain is set to 50%, then 50% of the error is output. The

setting range for Pgain is 0.0-1,000%. For ratios below 0.1%, use AP.26 (P

Gain Scale).

AP.23 PID I- Time

Sets the time to output accumulated errors. When the error is 100%, the

time taken for 100% output is set. When the integral time (PID I-Time) is set

to 1 second, 100% output occurs after 1 second of the error remaining at

100%. Differences in a normal state can be reduced by PID I Time. Also, a

digital input can be set to 21 (I-Term Clear) to clear all of the accumulated

errors.

AP.24 PID D-Time

Sets the output volume for the rate of change in errors. If the differential

time (PID D-Time) is set to 1ms and the rate of change in errors per sec is

100%, output occurs at 1% per 10ms.

AP.25 PID F-Gain

Sets the ratio that adds the target to the PID output. Adjusting this value

leads to a faster response.

AP.27 PID Out LPF

Used when the output of the PID controller changes too fast or the entire

system is unstable due to severe oscillations. In general, a lower value

(default value=0) is used to speed up response time, but in some cases a

higher value increases stability. The higher the value, the more stable the

PID controller output is, but the slower the response time.

AP.28 PID Mode

Process PID (0) or Normal PID (1). Process PID is used in applications when

the monitored (process) variable increases, the response is to decrease the

output of the inverter. In Normal PID applications, as the process variable

increases, the response is to increase the output of the inverter.

AP.29 PID Limit Hi,

AP.30 PID Limit Lo

Limits the output frequency of the controller.

AP.32 PID Out Scale Adjusts the volume of the controller output.

AP.42 PID Unit Sel

Sets the unit of the control variable.

Setting

Function

0

%

Displays a percentage without a physical quantity given.

1

Bar

Various units of pressure can be selected.

2

mBa

r

3

Pa

4

kPa

5

Hz

Displays the inverter output frequency or the motor rotation

speed.

6

rpm

7

V

Displays in voltage/current/power/horsepower.

8

I

9

kW

10 HP

11

°C

Displays in Celsius or Fahrenheit.

Summary of Contents for Rsi S Series

Page 2: ......

Page 6: ......

Page 12: ...Preparing the Installation 0...

Page 22: ...Preparing the Installation 10...

Page 70: ...LearningAdvanced Features 58...

Page 152: ...LearningAdvanced Features 140 PID controlblock diagram...

Page 224: ...LearningAdvanced Features 212...

Page 356: ...344...

Page 362: ...Maintenance 350...

Page 381: ...369 TechnicalSpecification...

Page 397: ......