Introduction

ix

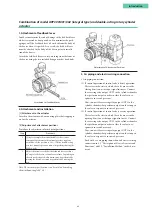

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the pack-

aging as well, the feedback lever is detached from the body of

the device when it is packed. As a result, the feedback lever

must be attached to the body of the device prior to installa-

tion of the device.

Attach the feedback lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Spring

Feedback lever

Bolt with hexagonal hole

Main unit

Attachment of Feedback Lever

2. Attachment and installation

[1] Attachment to the actuator

Attach to the actuator with a mounting plate that is appropri-

ate for the actuator.

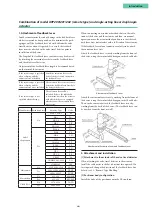

[2] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step

Procedure

1

Set the A/M switch to manual operation.

(See 5.2, “A/M Switch.”)

2

Supply air, and adjust the actuator air pressure such that the

actuator stem reaches the travel midpoint.

3

Adjust the actuator such that the feedback lever reaches a

90° angle to the device's central vertical axis. Depending

on the actuator being used, adjustment may be performed

by moving the device, or it may be performed by moving

the pin.

4

Set the A/M switch to automatic operation.

(See 5.2, “A/M Switch.”)

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ± 2°.

Combination of model AVP300/301/302 (integral type) and single-acting rotary cylinder

actuator

Adjustment of Attachment Positions

3. Air piping and electric wiring connection

Connect the air piping and electrical wiring.

For details, see section 2.2, “Installation Method,” in this

document.

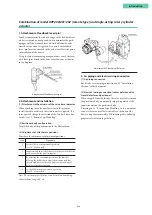

4. Auto-setup

(1) Set the input signal to 18 ± 1 mA.

(2) Using a flat-blade screwdriver, turn the external zero/

span adjustment switch in the upper part of the case 90°

in the UP direction (clockwise), and hold that position

for three seconds.

Note: For reverse close (when the valve's fully closed posi-

tion is on top), set the valve action to reverse close before-

hand. See 4.4.4, “Control configuration,” in this document.

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, adjust it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

• Auto-setup can be performed with CommStaff as well.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

Note: When closing the valve

of the single-acting type device

with the lever in the upward

direction, first set it to reverse

close.

If performing auto-setup

Rotate in UP direction

External zero/span adjustment switch

Summary of Contents for AVP200

Page 30: ......

Page 66: ...2 28...

Page 80: ...4 4 Menu Tree...

Page 120: ...5 16...

Page 128: ...6 8 For models those date of manufacture are before September 2017...

Page 130: ...6 10 For models those date of manufacture are before September 2017...

Page 132: ...6 12 For models those date of manufacture are before September 2017...

Page 136: ...6 16 For models those date of manufacture are after October 2017...

Page 138: ...6 18 For models those date of manufacture are after October 2017...

Page 184: ...Appendix A Specifications A 25...

Page 185: ......

Page 188: ......

Page 190: ......