84

CWI-078A

23. Apply oil to the connecting-rod small end bearings;

then install the small-end bearings.

24. Place each piston over the connecting rod so the indi-

cator arrow on each piston will point toward the

exhaust ports; then secure with an oiled piston pin.

NOTE: The indicator arrow is found on the piston

dome.

25. Install the new circlips so the open end is directed

either up or down.

26. Rotate each piston ring until the ring ends are prop-

erly positioned on either side of the ring keeper; then

apply oil to the piston assemblies and cylinder bores.

CWI-063

27. In turn on each cylinder, place a piston holder (or

suitable substitute) beneath the piston skirt and

square the piston in respect to the crankcase; then

using a ring compressor or fingers, compress the

rings and slide the cylinder over the piston. Remove

the piston holder and seat the cylinder firmly onto

the crankcase.

NOTE: The cylinders should slide on easily. DO

NOT force the pistons into the cylinders.

28. Install each cylinder with the eight existing nuts;

then secure the cylinders by tightening the cylinder

base nuts to 15 ft-lb then to 32 ft-lb in a crisscross

pattern.

29. Install the cylinder O-rings (lightly coated with oil)

on the top of each cylinder making sure they are cor-

rectly positioned in the grooves.

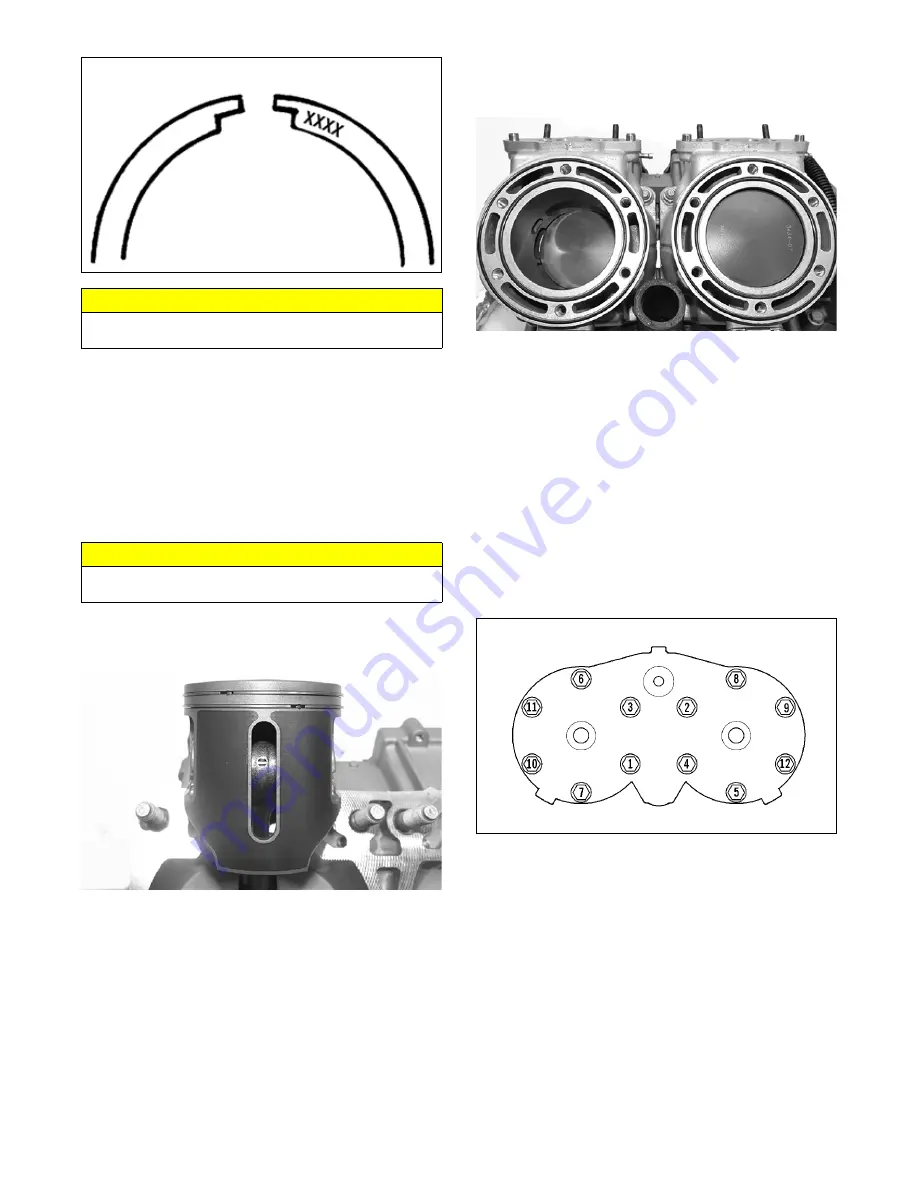

CWI-010

30. Place new O-rings (lightly coated with oil) onto each

of the head cap screws. Place four of these cap

screws (from opposite end of each other) into the

cylinder head. Thread the spark plugs in part way;

then while holding the head above the cylinder, care-

fully start and finger-tighten all four cap screws

while observing the cylinder O-rings to make sure

they remain in position. Slowly place the head into

position on top of the O-rings.

NOTE: To install the remaining cap screws, the

spark plugs must be removed.

31. Start and finger-tighten the cap screws being very

careful not to move the cylinder head; then tighten

the cap screws in two steps to 13 ft-lb then 25 ft-lb

using the pattern shown.

0747-890

NOTE: At this point, install the spark plugs; then

install the knock sensor. Tighten the sensor to 18 ft-lb.

32. Install the coolant inlet hose to the cylinder head and

water pump; then secure using the clamp.

33. Install the fuel rail assembly into the back of the cyl-

inders making sure the gaskets are in place; then

secure the rail using new nylon nuts. Tighten to 102

in.-lb.

CAUTION

Incorrect installation of the piston rings will result in

engine damage.

CAUTION

Make sure the circlips are firmly seated before continu-

ing with assembly.

Summary of Contents for M 8000

Page 1: ...www arcticcat com SERVICE MANUAL www arcticcat com...

Page 42: ...41 500cc_2A_15...

Page 50: ...49 600_14_2...

Page 58: ...57 800_12_2...

Page 155: ...154 Troubleshooting Servomotor SERVO1A16...

Page 156: ...155 SERVO2rv16...

Page 193: ...192 0747 414 M 141 High Country Models...

Page 209: ...208 NOTES...

Page 210: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2260 847...