139

7. With the idle position set to specification, slowly

compress the throttle lever to the full-open position.

The full-open specification should be observed. Gen-

tly snap the throttle lever open and closed several

times and note if the reading remains within the

specification.

NOTE: If, after adjusting the Throttle Position Sen-

sor to the IDLE specification, the FULL-OPEN is less

than the specified voltage, recheck the

FULL-CLOSED setting. If the FULL-CLOSED set-

ting is correct, replace the sensor.

REPLACING TPS (4000/8000)

NOTE: Replacing the TPS is for out of warranty

snowmobiles only.

Removing

1. Remove the expansion chamber and resonator.

2. Rotate the idle screw counterclockwise until it no

longer contacts the throttle shaft stop. The throttle

shaft should now be completely closed.

3. Disconnect TPS wiring harness from the TPS; then

noting the position of the TPS, remove the two

screws securing the TPS to the throttle body and

remove the sensor.

Installing

1. Apply a light film of silicone grease to the O-ring.

Install the O-ring into the groove.

2. Install the new TPS onto the throttle shaft by align-

ing the “flats” on the throttle shaft cam with the

“flats” on the sensor; then rotate the sensor until

properly positioned on the throttle body.

3. Install the sensor to the throttle body. Do not tighten

at this time.

4. Adjust the TPS (see appropriate Adjusting TPS in

this sub-section).

NOTE: Before installing the TPS harness connector,

apply dielectric grease to the connector pins.

5. Disconnect the adjustment tool harness from the

TPS. Connect the snowmobile TPS harness to the

newly installed or adjusted TPS.

6. Install the resonator and expansion chamber.

REPLACING TPS (6000)

NOTE: Replacing the TPS is for out of warranty

snowmobiles only.

Removing

1. Rotate the idle screw counterclockwise until it no

longer contacts the throttle shaft stop. The throttle

shaft should now be completely closed.

2. Disconnect TPS wiring harness from the TPS; then

noting the position of the TPS, remove the two

screws securing the TPS to the throttle body and

remove the sensor.

Installing

1. Install the new TPS onto the throttle shaft by align-

ing the “flats” on the throttle shaft cam with the

“flats” on the sensor; then rotate the sensor until

properly positioned on the throttle body.

NOTE: Before installing the TPS harness connector,

apply dielectric grease to the connector pins.

2. Install the sensor to the throttle body. Do not tighten

at this time.

3. Adjust the TPS using the CATT II Tool.

Electrical Resistance Tests

NOTE: Replace any component that does not have a

test value within specifications. If the component tests

satisfactorily but is suspected to be faulty, connect the

red meter lead to a component lead and the black

meter lead to ground. Check for continuity between

the component and ground. If continuity is observed,

replace the component.

NOTE: The following test should be made using

MaxiClips and the Fluke Model 77 Multimeter set to

OHMS scale.

Charge Coil (1)

1. Disconnect the triple-wire plug from the main har-

ness to the magneto.

2. Connect the red meter lead to the black/red wire in

the plug; then connect the black meter lead to the

green/red wire in the plug.

3. Resistance must be 8.8-13.2 ohms.

Charge Coil (2)

1. Disconnect the triple-wire plug from the main har-

ness to the magneto.

2. Connect the red meter lead to the brown/white wire

in the plug; then connect the black meter lead to the

green/red wire in the plug.

3. Resistance must be 8.8-13.2 ohms.

Fuel Pump Coil

NOTE: With the engine running, there should

14.5-17.5 DC volts supplied to the fuel pump for oper-

ation.

Engine

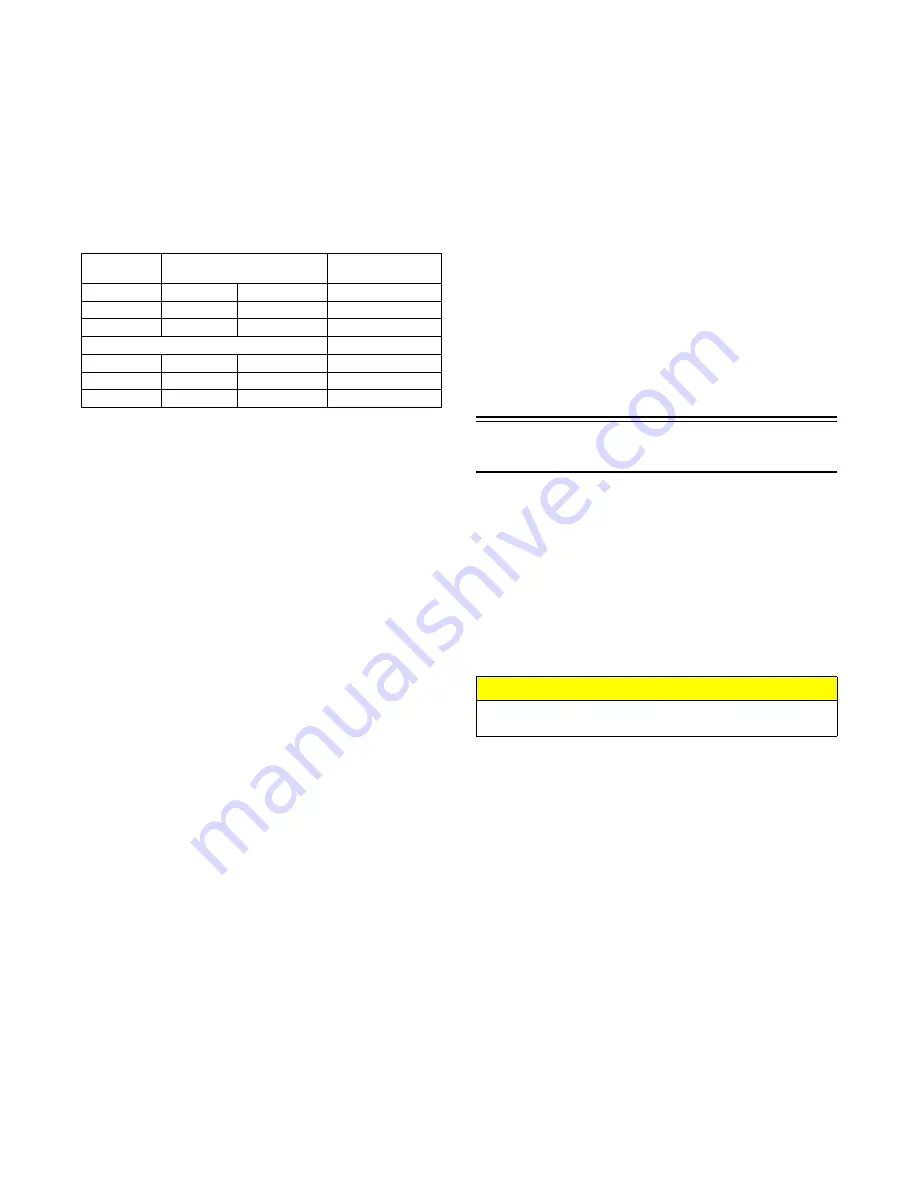

TPS TOOL (DC VOLTS)

ANALYZER TOOL

(DC VOLTS)

4000

Full-Closed

0.412-0.414

Idle 0.710-0.818

0.710-0.818

Full-Open

3.472-4.048

3.470-4.046

DIAGNOSTIC TOOL

8000

Full-Closed

0.412-0.414

Idle 0.646-0.754

3.99°

-6.66°

Full-Open

3.472-4.485

74.97°-89.37°

CAUTION

Always disconnect the battery when performing resis-

tance tests to avoid damaging the multimeter.

Summary of Contents for M 8000

Page 1: ...www arcticcat com SERVICE MANUAL www arcticcat com...

Page 42: ...41 500cc_2A_15...

Page 50: ...49 600_14_2...

Page 58: ...57 800_12_2...

Page 155: ...154 Troubleshooting Servomotor SERVO1A16...

Page 156: ...155 SERVO2rv16...

Page 193: ...192 0747 414 M 141 High Country Models...

Page 209: ...208 NOTES...

Page 210: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2260 847...