Page 5-3

IMPORTANT

1. Frequently clean the chuck.

2. When repeat accuracy is required, it is desired to tighten with the same

Pinion if it is the same diameter.

5.2 SPECIFICATIONS

Unit

:

mm

Model

Gripping range(mm)

Max. speed

O.D

I.D

(r.p.m)

SC-8

Ø4~ Ø 190

Ø 62~ Ø 180

2000

SC-9

Ø 5~ Ø 220

Ø 62~ Ø 210

2000

SC-10

Ø 6~ Ø 260

Ø 70~ Ø 250

1800

SC-12

Ø 10~ Ø 300

Ø 86~ Ø 290

1800

SC-16

Ø 30~ Ø 380

Ø 110~ Ø 360

1500

SK-8

Ø 8~ Ø 190

Ø 68~ Ø 180

2000

SK-9

Ø 11~ Ø 220

Ø 70~ Ø 210

2000

SK-10

Ø 12~ Ø 260

Ø 80~ Ø 250

1800

SK-12

Ø 15-~Ø 300

Ø 90~ Ø 290

1800

SK-16

Ø 30~ Ø 380

Ø 110~ Ø 360

1500

500(20”)

Ø 25~ Ø 280

Ø 150~ Ø 500

800

630(25”)

Ø 25~ Ø 350

Ø 170~ Ø 630

600

800(32”)

Ø 70~ Ø400

Ø 200~ Ø 800

500

5.3 INSTALLATIION

1. Adapter mounting accuracy is influenced to the chuck. Accordingly,

finish the adapter run-out and face run-out within 0.005mm after

mounting to spindle. If the run-out is more than 0.005mm, be sure to

modify.

Clean the chuck and adapter before mounting.

2. When using direct mount type, the joined area between the spindle and

the chuck is as shown in the Fig-2.

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

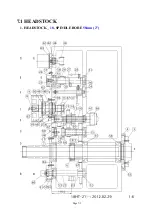

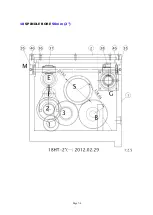

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...