Page 4-8

1. Lubricating Oil and Supplying Coolant

Always use the types of oil specified. Do not mix the oil of different brands

even if they are indicated as the “equivalent oil”. Original maker will not be

responsible for any problem arising from the use of oil not specified by + -.

2. Storing Oil

If oil is stored in user’s shop, observe the following points to prevent the oil

from being degraded. it is advisable to obtain only the amount of oil to be

used.

a) Store the oil in a place where it will not be subject to direct sunlight or

rain.

b) Keep the oil clean. No dirt or water should be allowed to enter the oil

storage tank.

c) Never use degraded oil or oil with foreign matter or water.

d) If middle tank is used. Clean the tank at least once a year.

3. Cautions when Replenishing Oil

a) Always use the same oil jug for the same oil. Never use a jug used for

different brand oil.

b) Never remove the filter from the filter port when supplying oil.

c) If oil other than specified by original maker, used mistakenly or different

brands of oil are mixed. Clean the tank and piping immediately.

4. Disposing Waste Oil

Disposing factory waste without legal permission is not allowed. Always ask

the service company when disposing oil.

5. Supplying Oil

Supplying Oil to the Slid way lubricating Oil Tank

a) Check the lubricating oil tank volume with the oil level gage installed on

the lubricating oil tank.

b) Remove the cap on the oil supply port.

c) Supply the specified lubricating oil from the oil jug while checking the oil

level with the oil level gauge.

6. Supplying Coolant to the Coolant tank

a)

Press the coolant off switch to stop coolant supply.

b)

Check the coolant tank volume with the oil level gage.

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

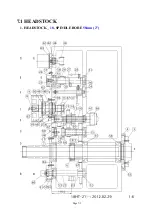

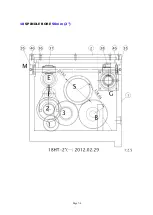

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...