Page 4-7

4.6 Notice for maintenance and inspection

Execute an emergency stop or switch off the main power supply before carrying

out maintenance and inspection work. If the machine is still in an operable

condition during this work and for example, a sensor is inadvertently touched,

the machine may move due care is therefore

required. Before operating the

machine, make sure that there is no obstacle to motion in the vicinity of the

machine.

1) Maintenance and inspection work must be performed without tail in order to

keep the machine operating at its highest performance and make it safe to

operate at all times.

2) Device maintenance and inspection plan and carry it out on a regular basis.

3) Proceed with maintenance and inspection as planned even if this interferes

with the production plan.

4) Before starting on the maintenance and inspection work, turn the power

switch off.

5) When working inside the electric control cabinet or repairing the machine, set

the power switch to the OFF position and lock it.

6) Do not use air to clean the machine. This may cause dust or sand particles to

cover the bearing or slide ways.

7) Use only lubricating oils which are recommended by + -

In order to operate machine correctly and make the most of machine’s functions

and performance, all operators must thoroughly understand the machine.

To keep the machine operating at its highest level, it must be inspected every

day. If an abnormality is discovered during daily inspection, it must be

reported to the supervisor and the person responsible for machine

maintenance.

Quick action should be taken. For problems that cannot be repaired by the user

or those for which the cause cannot be isolated, contact your + - service

representative.

Daily Replenishing Oil and Inspections by the machine Operator

↓

Maintenance and Repairs by maintenance Mechanics

↓

Service Request Call to our Representative

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

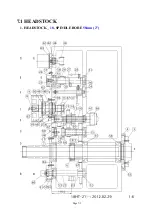

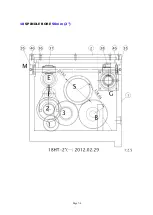

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...