Page 4-2

9) Keep adding new lubricant into the lubricant tank to sustain the lubricant

level.

10) After a while, turn off the lathe and the spindle. Disconnect the escape hose

from the container, and then connect back to the lubricant tank.

4.1.2

Fittings

Check all fittings after 500 hours of operation especially their tightness between

tubes. After that, do the regular check every 200 hours.

4.2 Machine body

In order to maximize the machine performance, the accuracy on headstock and

all slides have to be re-adjust after three months of operation. After that,

re-adjust every six months to one year to keep the machine in best accuracy.

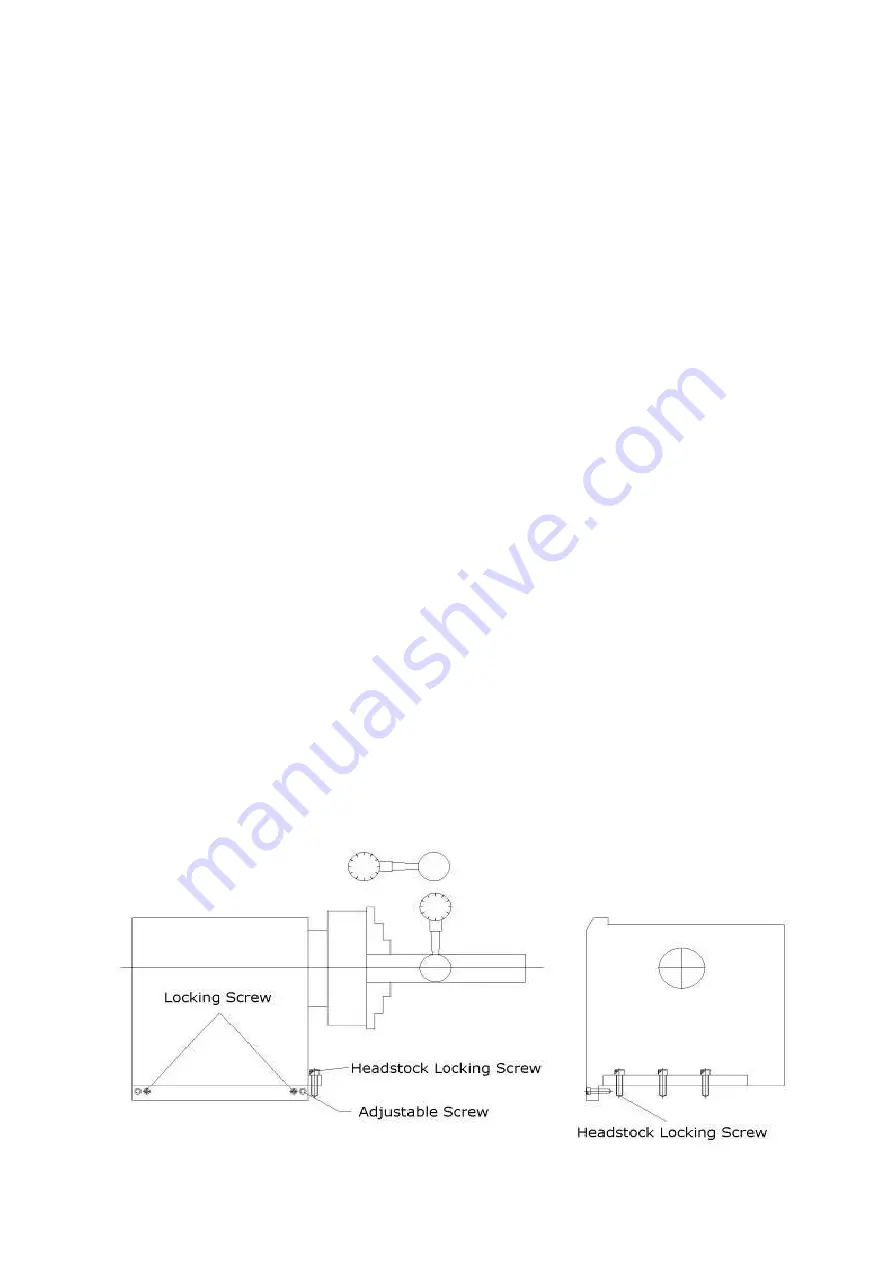

4.2.1 Aligning headstock

lf taper appears on turning work piece and convex on rounding, adjust the

parallel of headstock by following steps

1)

Insert gauge bar in the spindle bore. Attach the base of test indicator to the

tool post. Apply the stylus of the indicator to the outer diameter of the bar.

Move the saddle along Z axis and measure the maximal difference.

2)

If the pointer of the in indicator swings drastically, release the headstock

fixing screws and adjusting the adjusting to fine the paralleled of spindle and

Z axis

3)

After adjustment, tighten the fixing screws and move the saddle to observe

the pointer of the indicator.

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

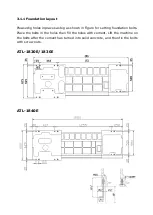

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

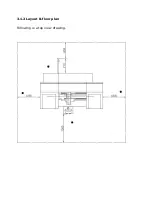

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...