3.4 Machine leveling

It is necessary to level the machine before starting to operate the machine.

Please prepare the following tools to adjust machine leveling:

1)

Accurate spirit leveling gauge (spec. 0.02mm/1000mm or 0.01in/4ft0

2)

Two adjustable wrench

Clean the table surface thoroughly, set one of the spirit leveling gauge on the

longitudinal direction and the other on the cross direction of the slide.

If there is only one leveling available, then use it on both directions alternately.

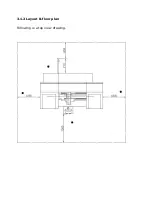

Adjust the six leveling screws bolts 1 located the bottom

of the machine base (as shown in below) until the machine

is leveled with 0.02mm/1000mm(0.001”/4ft) in both directions.

Suggestion: For the newly installed machine, check its once

every week. If the foundation is rigid enough, then you may

level the machine once per month.

3.5 Lubrication

3.5.1 Lubrication pump specification

Auto, manual pump tank capacity

:2.1 L

Effective capacity

:1.7 L

Motor

: (110V) / 220V

Directions

* Note the oil quantity will reduce gradually under normal application.

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

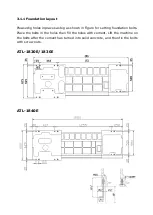

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...