Page 4-1

4. MAINTENANCE

4.1 Lubrication system

Check all the fitting of lubrication system under normal operation temperature.

If oil leaking is founds, tighten the fittings. Inspect oil level daily.

4.1.1

Replacing headstock oil

It is necessary to replace the oil for a new machine after one month. After first

replacement, it is recommended to replace the oil every

1300 operation

hours.

While replacing the oil, clean the oil tank thoroughly, just adding oil without

replacing, it is a waste of time and money for the new oil will not refresh the old

oil but deteriorating it. The metallic particle and dust in the old oil will form a

layer on the surface which will accelerate the oxidization of oil.

For replacing the lubricant, please refer to Figure 4-1 and follow the steps

below

:

1) The recommended lubricant is

Shell Telus 32 or Mobil DTE#24.

2) Prepare a large container at the front side of the headstock.

3) Turn off the lathe and the spindle. Disconnect the

escape hose from the lubricant tank, and then

connect to the container.

4) Turn on the lathe and the spindle. The old

lubricant will flow into the container instead.

5) Watch out the lubricant level of the lubricant tank

carefully. Turn off the lathe and the spindle,

when the lubricant tank is almost

empty.

6) Remove the plug of drain hole of the lubricant tank.

Drain out all the old lubricant and get the lubricant

tank really scoured. Then put the plug back.

7) Fill the lubricant tank with new lubricant.

8) Turn on the lathe and the spindle. The headstock

will be flushed by new lubricant, and the dirty

lubricant will flow into the container through the escape hose.

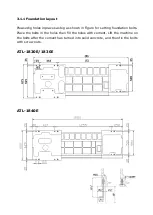

FIGURE 4-1

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

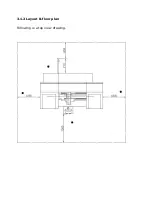

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...