3.3.3 Machine placing

Before placing the machine, fix the adjusting screws on the base, make the

machine as close as possible to the floor, and position the leveling pads in their

most suitable place, so as to increase the stability of machine.

3.3.4 MACHINE CLEAN & LUBRICATION

All protective coating must be removed before using the machine. Do not

attempt to move slideways if the coating still exists. Be cautions while selecting

a suitable cleaning agent, WD-40 applied with a clean brush will soften the

protective coating. The protective coating can then be removed with clean

rags.

NOTICE

1)

Do not use gasoline or any other flammable solution to clean the machine

2)

Clean and lubricate all the exposed ways of table and saddle. Drive the table

& saddle to one end of travel. Clean and lubricate ways thoroughly then drive

table & saddle to the other end and clean and lubricate ways thoroughly as

well. Be sure to use a suitable lubricant.

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

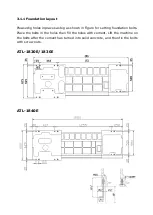

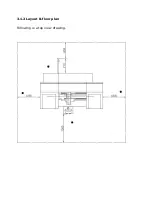

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...