3.6 Chucks and chuck mounting

NOTICE

Use only high-speed chucks which are capable of min. 3100RPM with these

machines.

3.6.1 Chuck fitting on spindle nose

When fit a

D type chuck

, it is necessary to fit a Back plate for chuck.

Fitting the Back plate first, then fit the chuck on. It would be easier to fit chuck

on when the Back plate is already well-fit on machine.

3.7 Tailstock center loading & unloading

To unload the center just hold the center and back the tail spindle.

Please wipe the taper of the center clean before loading it to the tail spindle.

3.8 Coolant

While choosing coolant for this machine, please ensure the material of the

coolant excludes material of Sulfur Chlorine. The Sulfur and Chlorine may

damage painting.

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

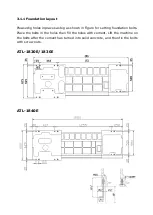

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

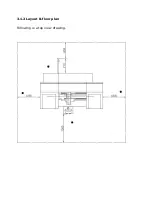

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...