Page 4-3

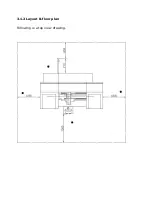

4.2.2 Cross slide

lf the gibs between slide and saddle become loose, it will affect the machining

You should regularly check and adjust them every six months according to the

following steps.

1)

Release the screw 1

2)

Remove slide cover 2 as shown as figure shown, then the gibs can be seen.

3)

Use flat head screw diver to release the adjust screw 3 about 1/2 circle

CCW

4)

Tighten screw 4 about 1/2 circle CW.

5)

Move the slide back and forth to a satisfied smoothness.

6)

Re-assemble the cover 2

4.2.2

4.2.3

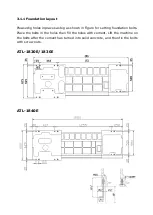

4.2.3 Saddle

lf the gibs between saddle and bed become loose, it will affect the accuracy of

saddle travel. Check and adjust them every six months according to the

following steps.

1)

Use flat head screw driver to loosen the adjust screw 1 & 2 as shown as Fig.

about 1/2 circle CCW.

2)

Appropriately tighten adjust screw 3 & 4 as shown in figure about 1/2 circle

CW.

3)

Move saddle left and right to a satisfied smoothness.

4.2.4 Aligning tailstock to spindle

If there is taper appearing on work piece while machining it by using

tailstock.

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...