Page 4-11

Monthly (250 H)

Maintenance

correctly function.

7.Clean the in-line filter in the headstock lubrication unit.

8.Check to be sure that wiring is properly done without

looseness or disconnection.

9.Check to be sure that the interlock devices and timers can

function normally.

10.Drain the coolant , clean inside the tank and hose and

then fill the coolant tank with new coolant.

Every six Months

(1500 H)

Maintenance

1. Carry out weekly maintenance.

2. Clean the NC equipment, electrical control unit and

machine.

3. Change the hydraulic oil in the hydraulic power unit and

the lubricant for the spindle head and the table. Before

supplying new hydraulic oil or lubricant, clean the inside of

the tanks.

4. Clean all the motors.

5. Check the bearing in the motor for noise. Replace the

bearings. If necessary.

6. Visually check the electrical devices and reply panel.

7. Check each indicator and the voltmeter if it is correct.

Adjust or replace it , if necessary.

8. Flash the lubrication pump ,clean the head lubricant filter

according the instructions provided by maker.

9. Check the machine movement and functions using a test

tape.

10. Measure the backlash in each drive shaft and adjust for

compensation date, if necessary.

Summary of Contents for ATL 1820E

Page 5: ...1 SAFETY INSTRUCTIONS ...

Page 22: ...Page 1 17 ...

Page 24: ...2 MACHINE SPECIFICATIONS ...

Page 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Page 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Page 31: ...3 INSTALLATION ...

Page 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Page 43: ...4 MAINTENANCE ...

Page 55: ...5 CHUCK ...

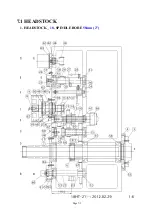

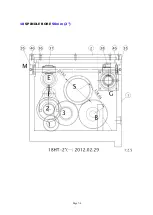

Page 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Page 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Page 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Page 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Page 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...