Mounting

D184B097U02

FV4000 / FS4000

25

4.3

Installation at high media temperatures

> 150°C (302°F)

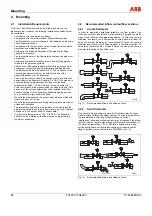

At high media temperatures > 150°C (302 F) the flowmeter sensor

must be installed so that the transmitter is pointing to the side or

downward (see the figure below).

G00616

Fig. 15

4.4

Installation for pressure and temperature

measurement

As an option, the flowmeter can be fitted with a Pt100 for direct

temperature measurement. This temperature measurement supports,

for example, the monitoring of the media temperature or the direct

measurement of saturated steam in mass flow units.

If pressure and temperature are to be compensated externally (e.g.

with the "Sensycal"), the measuring points must be installed as

illustrated in the figure below.

G00617

3 ... 5 D 2 ... 3 D

T

P

Fig. 16:

Arrangement of temperature and pressure measuring

points

4.5

Installation of final controlling equipment

Final controlling equipment must be arranged at the outflow end

spaced at a minimum 5 x DN.

G00615

5 x D

Fig. 17:

Installation of final controlling equipment

If the medium is conveyed through piston / plunger pumps or

compressors (pressures for fluids > 10 bar (145 psi)), it may be

subject to hydraulic vibration in the pipeline when the valve is closed.

If this does occur, the valve absolutely has to be installed in the flow

direction upstream of the flowmeter. The FS4000 Swirl flowmeter is

particularly suited to such scenarios. Suitable dampers (e.g. air

vessels in the case of pumping using a compressor) might need to be

used.

Summary of Contents for FS4000

Page 1: ...Operating Instruction D184B097U02 Vortex Flowmeter Swirl Flowmeter FV4000 FS4000 ...

Page 116: ...Appendix 116 FV4000 FS4000 D184B097U02 ...

Page 117: ...Appendix D184B097U02 FV4000 FS4000 117 ...

Page 118: ...Appendix 118 FV4000 FS4000 D184B097U02 ...

Page 119: ...Appendix D184B097U02 FV4000 FS4000 119 ...

Page 120: ...Appendix 120 FV4000 FS4000 D184B097U02 ...

Page 125: ......