Design and function

20

FV4000 / FS4000

D184B097U02

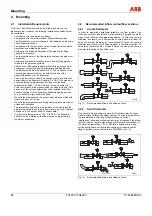

2.1.2 Swirl

flowmeter

The inlet pipe converts the axial flow of the incoming media into rotational movement. In the

center of this rotation a vortex core is formed which is forced into a secondary spiral-shaped

rotation by the backflow.

The frequency of this secondary rotation is proportional to the flow and, if the internal geometry

of the meter exhibits an optimum design, will be linear over a wide flow range. This frequency is

measured by a piezo sensor. The frequency signal from the flowmeter sensor, which is

proportional to the flow, undergoes downstream processing in the transmitter.

G00702

p1

V

T2

V

T1

V = 0

A

V = 0

A

p2

1

2

3

4

5

6

Fig. 8:

Principle of measurement of the Swirl flowmeter

G00601

1

3

5

4

2

Fig. 9:

Principle of measurement of FS4000-ST4/SR4 Swirl flowmeters

1 Inlet

pipe

2 Piezo

sensor

3 Outlet

pipe

4

Stagnation point

5

Housing

Summary of Contents for FS4000

Page 1: ...Operating Instruction D184B097U02 Vortex Flowmeter Swirl Flowmeter FV4000 FS4000 ...

Page 116: ...Appendix 116 FV4000 FS4000 D184B097U02 ...

Page 117: ...Appendix D184B097U02 FV4000 FS4000 117 ...

Page 118: ...Appendix 118 FV4000 FS4000 D184B097U02 ...

Page 119: ...Appendix D184B097U02 FV4000 FS4000 119 ...

Page 120: ...Appendix 120 FV4000 FS4000 D184B097U02 ...

Page 125: ......