Mounting

26

FV4000 / FS4000

D184B097U02

Change from one to two columns

4.6

General information on installation

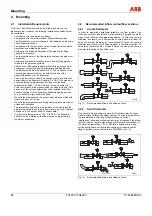

The following points must be observed during installation:

• The meter tube must always be completely full.

• The flow direction must correspond to the marking, if there is one.

• The maximum torque for all flange connections must be complied with.

• The meters must be installed without mechanical tension (torsion, bending).

• Wafer design flowmeters with coplanar counter flanges may only be installed with suitable

gaskets.

• Only gaskets made from a material which is compatible with the media and its temperature

may be used.

• Gaskets must not extend into the flow area since possible turbulence could affect the

accuracy of the meters.

• The pipelines must not exert any impermissible forces or torques on the meter.

• Do not remove the plugs in the connectors until you are ready to install the electrical cable.

• Make sure the gaskets for the housing cover are seated properly. Carefully gasket the cover.

Tighten the cover fittings.

• Do not expose the transmitter to direct sunlight and provide for appropriate sun protection

where necessary.

• When selecting the installation site, make sure that moisture cannot penetrate the terminal

housing or transmitter compartment.

• Make sure the signal cable connectors are plugged in and tightened properly to ensure IP 67

protection.

Summary of Contents for FS4000

Page 1: ...Operating Instruction D184B097U02 Vortex Flowmeter Swirl Flowmeter FV4000 FS4000 ...

Page 116: ...Appendix 116 FV4000 FS4000 D184B097U02 ...

Page 117: ...Appendix D184B097U02 FV4000 FS4000 117 ...

Page 118: ...Appendix 118 FV4000 FS4000 D184B097U02 ...

Page 119: ...Appendix D184B097U02 FV4000 FS4000 119 ...

Page 120: ...Appendix 120 FV4000 FS4000 D184B097U02 ...

Page 125: ......