Mounting

D184B097U02

FV4000 / FS4000

27

4.7

Mounting the meter tube

The flowmeter sensor can be installed at any location in a pipeline subject to compliance with

the installation conditions.

1.

Position the flowmeter sensor coplanar and centered between the pipes.

2.

Install gaskets between the surfaces of the flowmeter sensor and the counter flange.

Important

The flowmeter sensor gaskets and the flowmeter sensor must be centered. This will ensure

accurate measurement results. Do not allow the gaskets to extend into the pipeline.

Otherwise the flow profile will be distorted.

3.

Use the appropriate screws for the holes.

4.

Slightly grease the threaded nuts.

5.

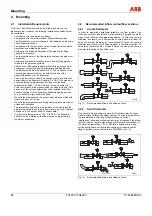

Tighten the nuts in a crosswise manner as shown in the figure. Observe the selected

tightening torque!

Important

Torques for screws depend on temperature, pressure, screw and gasket materials. The

relevant applicable regulations must be taken into consideration.

First tighten the nuts to approx. 50 % of the maximum torque, then to 80 %, and finally a third

time to the maximum torque. Do not exceed the maximum selected torque.

G00034

1

2

7

8

5

3

4

6

1

2

3

4

Fig. 18

Important

Tighten flange screws and nuts to prevent them coming loose. This is recommended in the

case of pipeline vibration. Supports/damping devices should always be installed to prevent

pipeline vibration.

Summary of Contents for FS4000

Page 1: ...Operating Instruction D184B097U02 Vortex Flowmeter Swirl Flowmeter FV4000 FS4000 ...

Page 116: ...Appendix 116 FV4000 FS4000 D184B097U02 ...

Page 117: ...Appendix D184B097U02 FV4000 FS4000 117 ...

Page 118: ...Appendix 118 FV4000 FS4000 D184B097U02 ...

Page 119: ...Appendix D184B097U02 FV4000 FS4000 119 ...

Page 120: ...Appendix 120 FV4000 FS4000 D184B097U02 ...

Page 125: ......