1726 North Ballard Road, Suite 1 - Appleton, WI 54911 - 920.991.9082

Technical Support 855.804.5774 - [email protected]

PTM30061-C

1/21/2013

W

E

CRUSH

HAZARD

CUTTING

HAZARD

CRUSH

HA

Z

ARD

CRUSH

HAZARD

FALLING

HAZARD

CRUSH

HAZARD

PINCH

HAZARD

PUNCTURE

HAZARD

ECO-SYSTEM

HAZARD

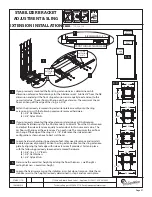

Step

1

Disassemble jack parts (leave bottom piston in bottom

sleeve) and bring into hoistway. Use a spanner wrench (142mm,

pin diameter 8mm) for this step. Use bell hoist for chain

hoisting parts into place. Clean all threads with a non-residual

solvent. Wood “V” blocks may help for maintaining jack position

while assembling.

Step

2

Set bottom assembly onto jack cup (refer to jack installation).

Step

3

Place O-ring between pistons. Do not crossthread! Thread top

piston & bottom piston together with provided thread locker until

painted lines match.

Step

4

Plumb and polish joint. Check for clear and smooth surface

between

pistons.

Step

5

Fit O-ring onto bottom of top sleeve.

Step

6

Using provided thread locker, thread top sleeve into bottom

sleeve. Use a spanner wrench (142mm, pin diameter 8mm) for

this step. Refer to jack installation for PRV positioning. Remember,

DO NOT CROSSTHREAD!

Step

7

Fasten top sleeve to jack bracket. If a second jack bracket is

provided, fasten to bottom sleeve (reference fi eld drawings for

bracket locations.

Step

8

Insert gland assembly into top sleeve.

Step

9

Fasten

fl ange assembly to top sleeve with socket head cap screws.

Refer to jack installation for overfl ow relief positioning.

Step

10

WAIT 24 HOURS BEFORE FILLING WITH OIL.

WARNING

DO NOT DISASSEMBLE THESE TWO ASSEMBLIES.

IF SEAL IS BROKEN, THE PARTS WILL NEED TO BE REPLACED.

ATTENTION

Make sure that all pistons, cylinder and components are kept from

damage, loss or contamination.

While threading be careful not to damage and/or scar the inside of top sleeve.

Return to Jack Installation Instructions

Carefully examine piston for damages, scratches, score marks or nicks.

The damage must be removed prior to changing or assembling seals,

using a 12” smooth fl at fi le, 180 and 240 grit emery cloth. Bad damage

can be removed using fi le on a 45° angle to the center line of piston,

fi nish the surface with 240 grit emery cloth.

BELL HOIST

FLANGE

O - RING

WIPER SEAL

MAIN SEAL

(TEXTURED

SIDE UP)

GLAND

TOP SLEEVE

O - RING

TOP PISTON

COLLAR

BOTTOM PISTON

BOTTOM SLEEVE

O - RING

BOLT

SERIES

114 - 116

TWO PIECE

JACK ASSEMBLY

Page 12

Содержание Paca-Ryde

Страница 2: ......

Страница 45: ...PAGE INTENTIONALLY LEFT BLANK ...

Страница 71: ......

Страница 72: ...PMI116 S APR 2018 1726 North Ballard Road Suite 1 Appleton WI 54911 Phone 920 991 9082 www waupacaelevator com ...