20

Operator Safety

In the operation of the robotic arm system, we must ensure the safety of

the operators first, with the general precautions listed in the table below.

Please take appropriate measures to ensure the safety of operators.

1. Each operator who uses the robotic arm system

should read the product user manual carefully.

Users should fully understand the standardized

operating procedures with the robotic arm, and

the solution to the robotic arm running error.

2. When the device is running, even if the robotic arm

seems to stop, the robotic arm may be waiting for

the signal and in the upcoming action status. Even

in such a state, it should be considered as the

robotic arm is in action.

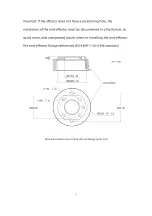

3. A line should be drawn to mark the range of

motion of the robotic arm to let the operator

acknowledge the robotic arm, including its end

tools (such as gripper and suction cup, etc)

operating range.

4. Check the robotic arm regularly to prevent

loosening of the bolts that may cause undesirable

consequences.

5. Be careful when the robotic arm is running too

fast.

6. Be careful about dropping items that can be

Содержание 850

Страница 1: ...1...

Страница 72: ...72 4 The control box PC and network switch are connected by Ethernet ca ble...

Страница 74: ...74 Step3 Open the Properties Step4 Open the IPV4...

Страница 89: ...89 Cancel Cancel the selection Save Save the modified data Discard Discard the modified data...

Страница 145: ...145 1 6 6 GPIO Control Box and End tool interface...

Страница 149: ...149 1 6 7 End Effector...

Страница 197: ...197 State 6 Stop Generally use studio will generate state 6 and state 6 is also a kind of stop...