Introduction

SIJECT 15/16 Operation Manual June, 2003

1-4

1.2

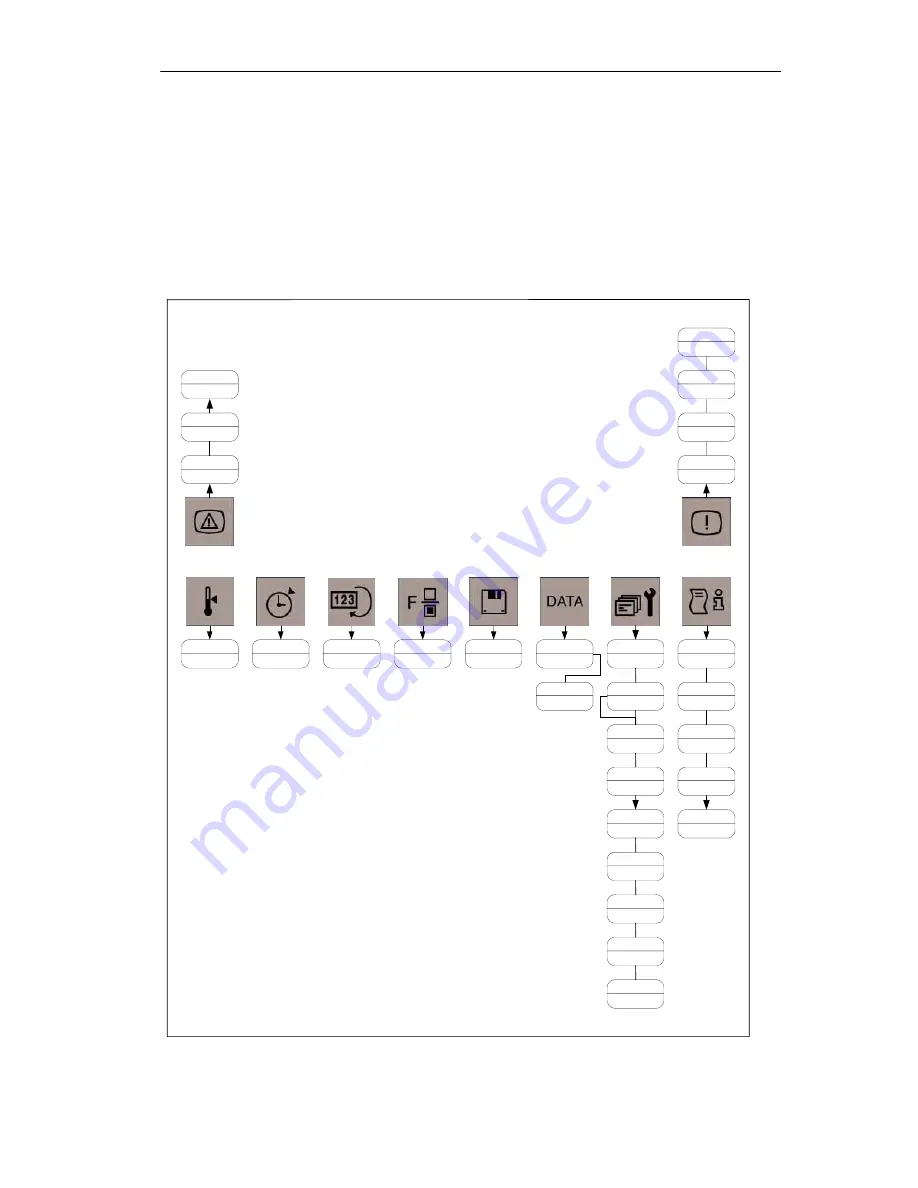

Overview of screens

Hot key screen

These screens are configured in different nested level. For instance, the

structure

Service screen

is designed in multistage structure, It is oriented to the

OEM-customer. Therefor it comprises the most important function

parameters for OEMs. Altogether nine different screens can be

displayed.

All hot key screens are listed in Table 1-2 for reference.

Table 1-2

Hot key screen structure

Screen 1

Temperature

Screen 1

Timer

Screen 1

Counter

Screen 1

Function

Screen 1

Load/save

Screen 1

Data

Screen 1

Service

Screen 1

Version inf

o

Screen 2

Data (con'd

)

Screen 1.1

Password

Screen 1.2

Load/save

Screen 1.1

OEM

Screen 1.3

Set prop.valve

Screen 2

Linear scale

Screen 1

Alarm

Screen 1

Monitoring

Screen 1.1

Event

Screen 2.1

Pump

Screen 2.2

Lubrication

Screen 2.3

Set function

Screen 2.4

Set ramp

Screen 1.2

DI

Screen 1.3

DO

Screen 2

PLC/CI Info

Screen 1.1

Event

Screen 1.2

Purge

Screen 1.3

Manual lube

Screen 2

Alarm(con'd)