iii

4.

Other instructions

The following instructions should also be fully noted. Improper operation may cause a damage,

fault, injury or electric shock, etc.

(1) Delivering and installation

Delivery the products correctly according to their weights.

It is not allowed to stack the products in excess of the specified layers.

Do not carry the motor by the cables, shaft or encoder.

Do not hold the front cover to transport the drive. Otherwise, it may be dropped.

The servo drive and motor must be installed in the specified direction.

Inside control box, preserve enough space between the servo drive and other equipment.

Provide adequate protection to prevent screws and other conductive matter, oil and other

combustible matter from entering the servo drive.

Do not drop or strike servo drive or servo motor. Keep from all impact loads.

Use the servo drive and servo motor under the specified environmental conditions.

Firmly attach the servo motor. Otherwise, it may come off during operation.

For safety of personnel, always cover the rotating and moving parts.

Never impact the servo motor or shaft, especially when coupling the servo motor to the

machine. The encoder may become faulty.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the

shaft may be broken.

When the equipment has been stored for an long period time, consult Shihlin.

(2) Wiring

In order to prevent from fire or other accidents, please use the cable specified in this user

manual to wire the servo equipment.

Wire the servo drive correctly and firmly. Otherwise, the motor will run improperly.

Do not install a power capacitor, surge absorber or noise filter between the servo motor

and servo drive.

Do not connect AC power directly to the servo motor. Otherwise, it results in damage of

servo motor.

The surge absorbing diode installed on the DC output signal relay must be wired in the

specified direction. Otherwise, the emergency stop and other protective circuits may not

operate.

Содержание SDE Series

Страница 13: ...5 1 6 Function block diagram ...

Страница 26: ...18 3 3 3 CN1 pin name list ...

Страница 212: ...204 SDE 075A2U SDE 100A2U 750W 1KW unit mm Dimensions of the servo drive may be revised without prior notice ...

Страница 223: ...215 SME L040 SME L075 SME L100 SME L150 ...

Страница 224: ...216 SME L200 SME L300 SME M100 SME M150 Continuous running range ...

Страница 225: ...217 SME M200 SME M300 NOTE These characteristic plots above are measured in case of 3φ 200 240V power supplied ...

Страница 227: ...219 ...

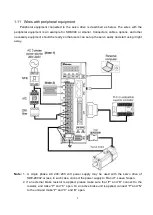

Страница 231: ...223 4 Wiring example with peripheral equipment CN2 Encoder socket ...

Страница 242: ...234 12 4 Version information Version V1 01 Issue date Aug 2017 Proofreader Yaochou Shu ...