56

SECTION 15 COMMISSIONING

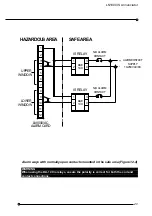

Commissioning and servicing operations must be carried out by a qualified technician

properly trained and authorised to work on intrinsically safe electronic equipment in

hazardous environments.

Tools required

Tools required are:

Small straight blade screwdriver for terminals

Medium straight blade screwdriver for terminal cover and panel mounting brackets

RTK supplied Double Hex 8mm socket for removal of front fascia

IS approved Multimeter (at least 20kohm/V)

Commissioning

1

Check all alarm contacts, external devices and remote pushbuttons for earth faults.

2

Check that all cables installed in the hazardous area are installed in accordance with

proper IS practice.

3

Check that all cables installed in the hazardous areas comply with the cable

parameters specified in Appendix A and in the certification documents.

4

Check that all wires are correctly terminated.

5

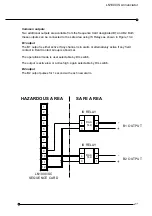

Power up and check the supply voltage between Terminal 1 & 2 on the Sequence

Card this should be between 7.5V and 8.5VDC.

6

Press the Test button and check all LED's, all segments of LCD's and any audibles

connected to the system operate correctly.

7

With all field contacts normal initiate the System Test sequence by pressing and

holding for 3 seconds the Silence and Test pushbuttons together. The test simulated

an alarm condition on all channels. All audible outputs are driven but not the group

outputs.

The Acknowledge and Reset pushbuttons are pressed to clear the alarms.

8

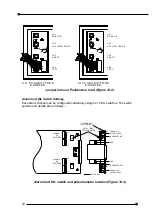

Set an alarm contact to abnormal and check the LED, LCD, audible and other outputs

follow the ISA sequences specified. Complete the process by pressing Silence,

Acknowledge, returning the field contact to normal and pressing the Reset buttons.

9

Set several alarm contacts to abnormal and repeat the test detailed in part (8) above.

This time also check that the first-up and only the first-up alarm is showing the "F"

correctly

10

Systematically check every alarm channel as part (8) above.