B

C

A

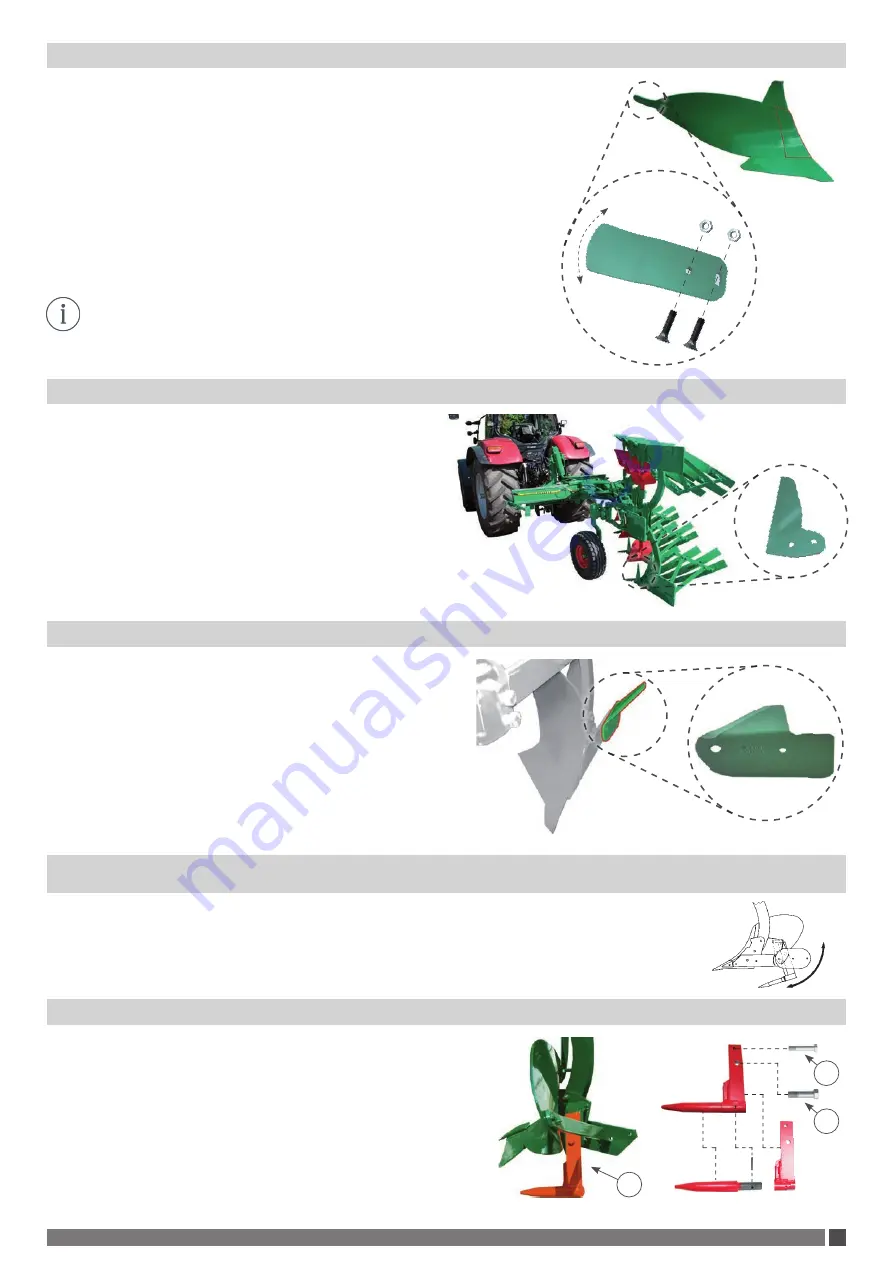

SUBSOIL DECOMPACTER MANDREL

System V-250 „screwed“

Levelling bar

Knife coulter

Wide furrow cutter

The levelling bars are used to create an even and level soil-surface and to gently

press the turned earth beam on the slope.

The intensity can be adjusted slightly.

Proceed as follows to adjust:

¾

Loosen the screws „A“ and „B“.

¾

Adjust the levelling bar by moving the outer end of it up or down.

¾

Tighten the screws „A“ and „B“.

In particularly sticky conditions (when soil sticks on to the mouldboards), the

levelling bars should be completely removed. In this case, the mouldboard

support strut can be mounted directly to the mouldboard, a distance instead

of the levelling bar is not necessary.

Optional knife coulters can be used instead of disc coulters on the

last plow body or, in difficult conditions, on all plow bodies. The

use of knife coulters on all plow bodies significantly improves plow

control, the plow reacts less intensively to uneven terrain and runs

very stable in the furrow.

To retrofit knife coulters, a small area of the mouldboard tip has to

be ground away.

The knife coulters are mounted fix to the trunk.

Optional wide furrow knives are used with extra wide towing vehic

-

le tires and operation in the furrow (no on-land). The wide furrow

knives cut into the side of the furrow edge and causing it to break

in at an angle. The crumbling material is deposited (dumped) in

the furrow behind the plow body. This creates a very wide (but a

little shallower) furrow.

This can be an advantage especially for short plow body types

with a less wide furrow clearance in combination with wider tires or

for plow bodies for deep plowing.

Subsoilers can be installed to work on the principle of “loosening deeply, turning shallowly”, or to break up a

compacted plow-base and loosen the soil in the depths. For the latter, special attention should be paid to the

soil moisture, since with higher soil moisture a smear layer can quickly develop in the deeper soil layers.

With the AS 250 system, the mandrel “A” and the mounting plate

are firmly screwed to the plow leg. The mandrel is mounted with 2

screws, a large rotary screw „B“ and a smaller shear screw „C“. In

the event of an overload, either the subsoiler‘s shear „C“ bolt or

the plow´s shear bolt (see chapter standard overload protection)

breaks and must be replaced immediately.

To park the plow, the subsoiler on the ground side must be comple

-

tely dismantled.

18

www.regent.at