A heat treating furnace is required to harden a mold at a high temperature

(1000 °C) for 30 minutes, then the mold is cooled down with a programmable

ramp ( 20 °C / minute ) toward a lower set point ( 200 °C ). Use the dual set

point / PID and ramp / dwell functions for this application.

A heat treating furnace is required to harden a mold at a high temperature

(1000 °C) for 30 minutes, then the mold is cooled down with a programmable

ramp ( 20 °C / minute ) toward a lower set point ( 200 °C ). Use the dual set

point / PID and ramp / dwell functions for this application.

Example 2: Dual Set Point / PID

Example 2: Dual Set Point / PID

( 1 ) Set the following parameters in the Setup menu:

( 1 ) Set the following parameters in the Setup menu:

FUNC= FULL

A1FN= TIMR

EIFN= SP.P2

PVMD= PV1

SPMD= MINR

FUNC= FULL

A1FN= TIMR

EIFN= SP.P2

PVMD= PV1

SPMD= MINR

( 2 ) Adjust the following parameters in the User menu:

( 2 ) Adjust the following parameters in the User menu:

TIME= 30.0 ( Minutes )

RAMP= 20.0 ( °C/Minute )

SP1= 1000 °C

SP2= 200 °C

PL1= 100 ( % )

TIME= 30.0 ( Minutes )

RAMP= 20.0 ( °C/Minute )

SP1= 1000 °C

SP2= 200 °C

PL1= 100 ( % )

( 3 ) Set the proper values for PB1, TI1, TD1,PB2, TI2 and TD2 according

to previous records. For a new system, first tune the PID set at SP1=800 °C

and tune the second PID set at SP2=400 °C.

( 3 ) Set the proper values for PB1, TI1, TD1,PB2, TI2 and TD2 according

to previous records. For a new system, first tune the PID set at SP1=800 °C

and tune the second PID set at SP2=400 °C.

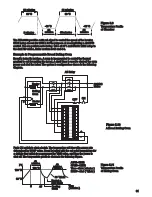

The circuit diagram is same as shown in Figure 5.14. The temperature profile

is shown as below:

The circuit diagram is same as shown in Figure 5.14. The temperature profile

is shown as below:

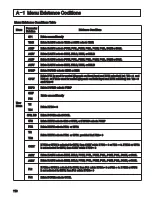

Figure 5.16

Figure 5.16

Dual Set Point /PID Profile

Dual Set Point /PID Profile

30

minutes

30

minutes

40

minutes

40

minutes

1000

200

Use SP1,PID1

Use SP1,PID1

Use SP2,PID2

Use SP2,PID2

C

Time ( Minutes )

Time ( Minutes )

95