60 minutes

60 minutes

60 minutes

60 minutes

60 C

60 C

60 C

60 C

5 minutes

5 minutes

30

minutes

30

minutes

35

minutes

35

minutes

65 minutes

65 minutes

-10 C

-10 C

-10 C

-10 C

Figure 5.9

Figure 5.9

Temperature Profile

of Chamber

Temperature Profile

of Chamber

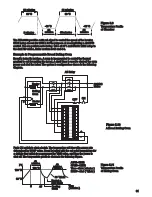

Example 2: Programmable Bread Baking Oven

Example 2: Programmable Bread Baking Oven

Bread is baked in batches. A ramp is incorporated to control the thermal

gradient to suit for making the bread. A dwell timer is used to shut off the oven

power and alert the baker. The system is configured as shown in the following

diagram.

Bread is baked in batches. A ramp is incorporated to control the thermal

gradient to suit for making the bread. A dwell timer is used to shut off the oven

power and alert the baker. The system is configured as shown in the following

diagram.

Figure 5.10

Figure 5.10

A Bread Baking Oven

A Bread Baking Oven

+

+

AC Relay

AC Relay

OFF

ON

220VAC

Mains

220VAC

Mains

Heater

Heater

Baking

Oven

Baking

Oven

Push ON switch to start a batch. The temperature will rise with a ramp rate

determined by RAMP value. Bread is baked with the set point temperature for

a definite time which is programmed by TIME value, and then the power is

shut off. The temperature profile is shown in the following Figure.

Push ON switch to start a batch. The temperature will rise with a ramp rate

determined by RAMP value. Bread is baked with the set point temperature for

a definite time which is programmed by TIME value, and then the power is

shut off. The temperature profile is shown in the following Figure.

The

-8300 provides 4-20 mA signal to control the speed of the Inverter.

SP.P2 being chosen for EIFN is for the purpose of accomplishing a dual PID

control. You can perform auto-tuning twice at SP1 and SP2 for initial setup to

the dual PID values. Refer

and

.

ETR

sections 3-19

4-3

The

-8300 provides 4-20 mA signal to control the speed of the Inverter.

SP.P2 being chosen for EIFN is for the purpose of accomplishing a dual PID

control. You can perform auto-tuning twice at SP1 and SP2 for initial setup to

the dual PID values. Refer

and

.

ETR

sections 3-19

4-3

40

minutes

40

minutes

40

minutes

40

minutes

180 C

180 C

180 C

180 C

Cooling

down

Cooling

down

Restart a

new batch

Restart a

new batch

30 C/min

30 C/min

PV

30 C

30 C

5

45

Time

( minutes )

Time

( minutes )

A1FN=TIMR

SPMD=MINR

Time=40.0 ( minutes )

RAMP=30.0 ( C/min )

A1FN=TIMR

SPMD=MINR

Time=40.0 ( minutes )

RAMP=30.0 ( C/min )

Figure 5.11

Figure 5.11

Temperature Profile

of Baking Oven

Temperature Profile

of Baking Oven

91

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20