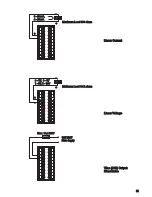

3 4 Heat Only Control

3 4 Heat Only Control

Heat Only ON-OFF Control : Select REVR for OUT1, Set PB1 to 0, SP1 is used

to adjust the set point value, O1HY is used to adjust the dead band for ON-OFF

control, TIME is used to adjust the dwell timer (enabled by selecting TIMR for

A1FN or A2FN). The output 1 hysteresis(O1HY) is enabled when the

proportional band is set to 0(off). The heat only on-off control function is shown

in the following diagram :

Heat Only ON-OFF Control : Select REVR for OUT1, Set PB1 to 0, SP1 is used

to adjust the set point value, O1HY is used to adjust the dead band for ON-OFF

control, TIME is used to adjust the dwell timer (enabled by selecting TIMR for

A1FN or A2FN). The output 1 hysteresis(O1HY) is enabled when the

proportional band is set to 0(off). The heat only on-off control function is shown

in the following diagram :

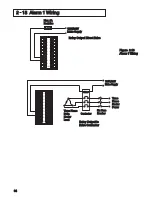

SP1+O1HY/2

SP1 O1HY/2

SP1

ON

OFF

OUT1 Action

PV

Dead band = O1HY

Time

Time

The ON-OFF control may introduce excessive process oscillation even if

hysteresis is minimized. If ON-OFF control is set ( ie. PB1 = 0 ), TI1, TD1,

CYC1, OFST, CPB and PL1 will be hidden and have no function to the system.

The manual mode, auto-tuning, self-tuning and bumpless transfer will be

disabled as well.

Select REVR for OUT1, set TI1 to 0, SP1 is used

to adjust set point value, TIME is used to adjust the dwell timer (enabled by

selecting TIMR for A1FN or A2FN). When TI1=0 the OFST parameter is used

to adjust the offset or “manual reset”. Adjust CYC1 according to the output 1

type (O1TY) .Generally, CYC1= 0.5 ~ 2 sec for SSRD and SSR, the

CYC1=10 ~ 20 sec for a relay output. CYC1 is ignored if the linear output is

selected for O1TY.

if Proportional band(PB1) is not equal to 0.

OFST is measured by % with a range of 0 - 100.0 %. Under a

steady state, (ie. the process temperature has been stabilized) if the process

value is lower than the set point by a definite value of say 5 °C, while 20 °C is

used for PB1, that is lower 25 %, then increase the OFST 25 %, and vice versa.

After adjusting the OFST value, the process value will be varied and eventually,

coincide with set point. Using the P control ( TI1 set to 0 ), the auto-tuning and

self-tuning are disabled.Refer to Section 3-20 " manual tuning " for the

adjustment of PB1 and TD1. The Manual reset adjustment (OFST) is not

practical because the load may change from time to time and require repetitive

OFST adjustments. The PID control will prevent this situation.

Selecting REVR(heating) for OUT1, SP1 is used to adjust

the set point value. TIME is used to adjust the dwell timer ( enabled by selecting

TIMR for A1FN or A2FN ). PB1 and TI1 should not be set to zero. Adjust CYC1

according to the output 1 type ( O1TY ). Generally, CYC1 = 0.5 ~ 2 sec for

SSRD and SSR, the CYC1 = 10 ~ 20 sec for a relay output. CYC1 is ignored if

linear output is selected for O1TY. In most cases, the self-tuning can be used to

substitute the auto-tuning. See

If self-tuning is not used (select

NONE for SELF), then use auto-tuning for the new process, or set PB1, TI1 and

TD1 with historical values. See section 3-19 for auto-tuning operation. If the

control result is still unsatisfactory, then use manual tuning to improve the

control . See Section 3-20 for manual tuning.

-

contains a

algorithm to achieve a

to the process if it is properly tuned.

Heat only P (or PD) control :

O1HY is hidden

OFST Function :

Heat only PID control :

Section 3-18.

ETR 8300

very

sophisticated PID and Fuzzy

very small overshoot and

very quick response

The ON-OFF control may introduce excessive process oscillation even if

hysteresis is minimized. If ON-OFF control is set ( ie. PB1 = 0 ), TI1, TD1,

CYC1, OFST, CPB and PL1 will be hidden and have no function to the system.

The manual mode, auto-tuning, self-tuning and bumpless transfer will be

disabled as well.

Select REVR for OUT1, set TI1 to 0, SP1 is used

to adjust set point value, TIME is used to adjust the dwell timer (enabled by

selecting TIMR for A1FN or A2FN). When TI1=0 the OFST parameter is used

to adjust the offset or “manual reset”. Adjust CYC1 according to the output 1

type (O1TY) .Generally, CYC1= 0.5 ~ 2 sec for SSRD and SSR, the

CYC1=10 ~ 20 sec for a relay output. CYC1 is ignored if the linear output is

selected for O1TY.

if Proportional band(PB1) is not equal to 0.

OFST is measured by % with a range of 0 - 100.0 %. Under a

steady state, (ie. the process temperature has been stabilized) if the process

value is lower than the set point by a definite value of say 5 °C, while 20 °C is

used for PB1, that is lower 25 %, then increase the OFST 25 %, and vice versa.

After adjusting the OFST value, the process value will be varied and eventually,

coincide with set point. Using the P control ( TI1 set to 0 ), the auto-tuning and

self-tuning are disabled.Refer to Section 3-20 " manual tuning " for the

adjustment of PB1 and TD1. The Manual reset adjustment (OFST) is not

practical because the load may change from time to time and require repetitive

OFST adjustments. The PID control will prevent this situation.

Selecting REVR(heating) for OUT1, SP1 is used to adjust

the set point value. TIME is used to adjust the dwell timer ( enabled by selecting

TIMR for A1FN or A2FN ). PB1 and TI1 should not be set to zero. Adjust CYC1

according to the output 1 type ( O1TY ). Generally, CYC1 = 0.5 ~ 2 sec for

SSRD and SSR, the CYC1 = 10 ~ 20 sec for a relay output. CYC1 is ignored if

linear output is selected for O1TY. In most cases, the self-tuning can be used to

substitute the auto-tuning. See

If self-tuning is not used (select

NONE for SELF), then use auto-tuning for the new process, or set PB1, TI1 and

TD1 with historical values. See section 3-19 for auto-tuning operation. If the

control result is still unsatisfactory, then use manual tuning to improve the

control . See Section 3-20 for manual tuning.

-

contains a

algorithm to achieve a

to the process if it is properly tuned.

Heat only P (or PD) control :

O1HY is hidden

OFST Function :

Heat only PID control :

Section 3-18.

ETR 8300

very

sophisticated PID and Fuzzy

very small overshoot and

very quick response

Figure 3.2 Heat Only

ON-OFF Control

Figure 3.2 Heat Only

ON-OFF Control

Setup ON-OFF :

Adjust :

OUT1 =

PB1 = 0

SP1, O1HY, TIME(if enabled)

Setup ON-OFF :

Adjust :

OUT1 =

PB1 = 0

SP1, O1HY, TIME(if enabled)

Setup P:

OUT1 =

TI1 = 0

CYC1 ( if RELAY, SSRD or SSR is

selected for O1TY )

Setup P:

OUT1 =

TI1 = 0

CYC1 ( if RELAY, SSRD or SSR is

selected for O1TY )

Adjust :

SP1, OFST, TIME ( if enabled ),

PB1 ( = 0 ), TD1

Adjust :

SP1, OFST, TIME ( if enabled ),

PB1 ( = 0 ), TD1

Setup PID :

Adjust:

OUT1 =

O1TY

CYC1 ( if RELAY, SSRD or SSR is

selected for O1TY )

SELF = NONE or YES

SP1, TIME ( if enabled ), PB1 ( = 0 ),

TI1 ( = 0 ), Td1.

Setup PID :

Adjust:

OUT1 =

O1TY

CYC1 ( if RELAY, SSRD or SSR is

selected for O1TY )

SELF = NONE or YES

SP1, TIME ( if enabled ), PB1 ( = 0 ),

TI1 ( = 0 ), Td1.

Auto-tuning:

Used for new process. during initial

tuning

Auto-tuning:

Used for new process. during initial

tuning

Self-tuning:

Used for a process any time.

Self-tuning:

Used for a process any time.

Manual Tuning:

May be used if self-tuning and

auto-tuning are inadequate.

Manual Tuning:

May be used if self-tuning and

auto-tuning are inadequate.

43