CDM816D WHEEL LOADER

71

2.

Check and add the brake-fluid of the machine. (Note: A brake-fluid of the same model as the

original fluid must be used. Otherwise, the original fluid must be completely emptied through a port

near the brake caliper and add a new brake-fluid);

3.

Check the oil level of the final reducer at each end of the drive axle, and the oil level of the main

reducer in the center of the axle housing; add oil as necessary (Note: Oil of the same model as the

original oil must be used; Otherwise, the service life of the oil will be affected.).

4.

Start the machine, and after finishing one to two operating cycles, lower the arm to the ground and

then stop the engine, inspect the oil levels in the hydraulic oil tank and the transmission and replenish

the tanks as necessary (Note: Oil of the same model as the original oil must be used; otherwise, the

service life of the oil will be affected);

5.

Check the gap between any brake pad and the matching brake disk and make replacements as

necessary; Tighten the fixed bolts and nuts on all transmission shafts to ensure that no loose bolt or

nut exists;

6.

Carry out the following operations if these 50-hour maintenance items are performed on the

machine for the first time, or skip it: replace the engine oil, engine oil filter and diesel oil filter elements;

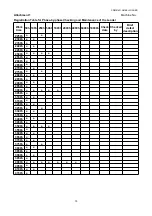

III. Maintenance items to be performed once every 100 hours or every half a month

1.

Remove foreign articles from all air-cooled radiator surface of the machine to ensure that the

cooling system can operate normally;

2.

Carry out the following operations if these 100-hour items are performed on the machine for the

first time, or skip it: replace the transmission oil, the oil filters of the transmission and torque converter

and the outer oil filter of transmission and torque converter; (the filter is optional, not for all machines)

open the bottom cover of the transmission; clean the filter net and the magnet carefully and then put

them back in place;

IV. Maintenance items to be performed once every 250 hours or every month

1.

Check the air intake system of the engine. Visually check the service indicator of the air filter.

Clean or replace the filter element of the air filter if the yellow piston of the indicator rises into the red

region;

2.

Replace the engine oil, the engine oil filter, the fuel oil filter and the oil-water separator filter

element. (The filter is optional, not for all machines.)

3.

Adjust the tension of the driving pulley of the engine and the air conditioning compressor belt and

the generator belt, check the damaged condition and replace it if necessary. Tighten all bolts fixed the

battery and clean its top;

4.

Check the working device, weld seam of the front and rear parts of the frame and fixed bolts

whether they have cracks or loosening.

5.

Carry out the following operations if these 250-hour items are performed on the machine for the

first time, or skip it: collect and filter the working hydraulic oil, replace the oil intake filter element,

replace the return oil filter element for the working hydraulic oil, clean the inside of the hydraulic oil

tank, return the filtered hydraulic oil to the hydraulic oil tank, and replenish the hydraulic oil tank as

necessary to ensure an appropriate oil level in the tank; (Note: When replacing the hydraulic oil filter