Operation Manual

68

2.

Always prevent impact on the battery causing fracture to its case during removing and installing.

3.

The battery is equipped with a plastic case which can bear limited pressure and tension force on

four edges due to its plasticity. The fixed locking bolt of the battery shall not be fastened tightly to avoid

leakage of battery acid solution due to the splitting of seals around the battery case. Burn the crack flat

with an iron strip locally padded after cleaning the outer surface if local split is found around the seal.

4.

Store the battery added with electrolyte after full charging, and start the loader to charge the

battery once at least during 1~3 months.

I.

Lubrication

Correct lubrication can significantly reduce the frictional resistance to the loader and wear to parts,

thus ensuring the normal operation of the loader and extending its service life.

Notes on Fuel Filling:

1.

Clean the fuel filling containers and parts, in case of damage to butter nipple, immediately replace

it;

2.

Always maintain the loader in a level state when checking the oil quantity;

3.

For the front and rear axles, add oil from the oil filling hole in the left and right wheel housings until

oil spills from the oil level plug in axle housing;

4.

For the transmission, the upper oil level check plug shall be taken as the benchmark, and the oil

level shall be between the upper and lower oil level check plug. The working oil tank shall be filled up

to the oil pointer (between the upper and lower oil pointer hole). In the filling for the first time, start the

engine and allow it running for 5 min and then check the oil level.

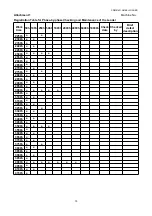

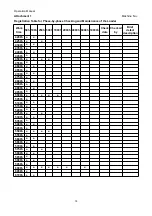

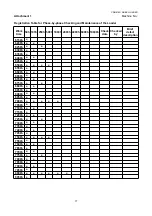

(2) Type and Grade of Lubricant (See Table 3-2)

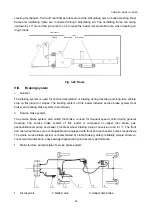

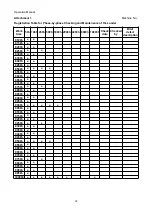

(3) Filling oil and injecting grease with pressure

1.

Diesel engine oil

It is used to lubricate the diesel engine. The marking line “Static Full” on the oil dipstick indicates the oil

level required before the diesel engine starts; the “Dynamic Full” indicates the oil level required to be

maintained when the diesel engine is running; the “Danger” indicates that oil shall be added

immediately. The oil shall be changed at 50 h (running-in expires) for the first time and then every 200

h.

2.

Oil for torque converter and transmission

Add oil from the transmission oil filler until the oil can be drained from the upper drain plug. The

minimum oil level shall not be lower than the drain plug after the engine starts. The oil is used for

torque transmission and lubrication, which shall be changed at 12 h for the first time and then every

600 h.

3.

Oil for drive axle

Add oil from the oil filler on left and right wheel housing until the oil spills when the oil plug in the middle

of axle housing is opened. The oil is used to lubricate the main reducer and wheel-side reducer, which

shall be changed at 200 h for the first time and then every 1,200 h.