Operation Manual

14

1.5.2.1 In the operation of machine, do not wear loose clothes or jewels which may enmesh or lock

the control handle or other parts on the equipment.

1.5.2.2 Make sure that all guard plates and covers are fixed on the corresponding locations of the

equipment.

1.5.2.3 Never pile up debris on the machine. Clear the debris, oil, tools, etc. on the machine floor,

channel and ladder.

1.5.2.4 Properly keep the scattered items, such as the lunch boxes, tools and other items which are

not the machine parts.

1.5.2.5 Be familiar with the specific hand signals on the site, and only receive the signals sent by a

person

1.5.2.6 Do not smoke in the maintenance of air conditioner or in the places possibly with refrigerant

gas. Inhaling the smoke released by the combustion of AC refrigerant may cause personnel injury or

death.

1.5.2.7 Do not put the maintenance fluids into the glass containers and discharge all maintenance

fluids into a suitable container.

1.5.2.8 Carefully use the detergent and report all the items in need of overhaul.

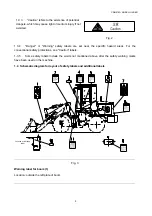

1.5.3

Check of machine

1.5.3.1 Before starting the machine each day or shift, walk around the machine to check it carefully,

so as not to cause economic loss or personnel injury

1.5.3.2 Check if the fixing levers for locking of front and rear frames are at the unlock position;

1.5.3.3 Check if each instrument is working normally. Start the engine only in the cab. Never short the

starter motor terminal or battery. Short circuit may cause the starting failure of engine and also the

damage to the circuit system.

1.5.3.4 Adjust the seat so that the driver is still able to press the pedal to the end when sitting against

the backrest.

1.5.3.5 Check the seat belts and fasteners. Replace the damaged or worn parts. Regardless of the

appearance, replace the seat belt used for three years.

1.5.3.6 Ensure the good vision around the cab with the scene outside the cab clearly displayed.

1.5.3.7 Make sure that the lighting system will meet the requirements of working conditions and all of

the lighting lamps can work properly.

1.5.3.8 Do not leave the parts and tools around the seat of operator. Due to the vibration in the

walking and operation, these things may fall and damage the control lever or switch or make the

control lever move to start the working device, leading to accidents.

1.5.3.9 Check the coolant level, fuel oil level and engine lubricating oil level, and check if the air filter

is clogged.

1.5.3.10 It is recommended that the machine is equipped with fire extinguishers. Operator shall know