CDM816D WHEEL LOADER

63

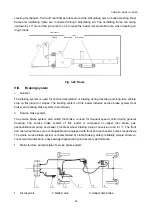

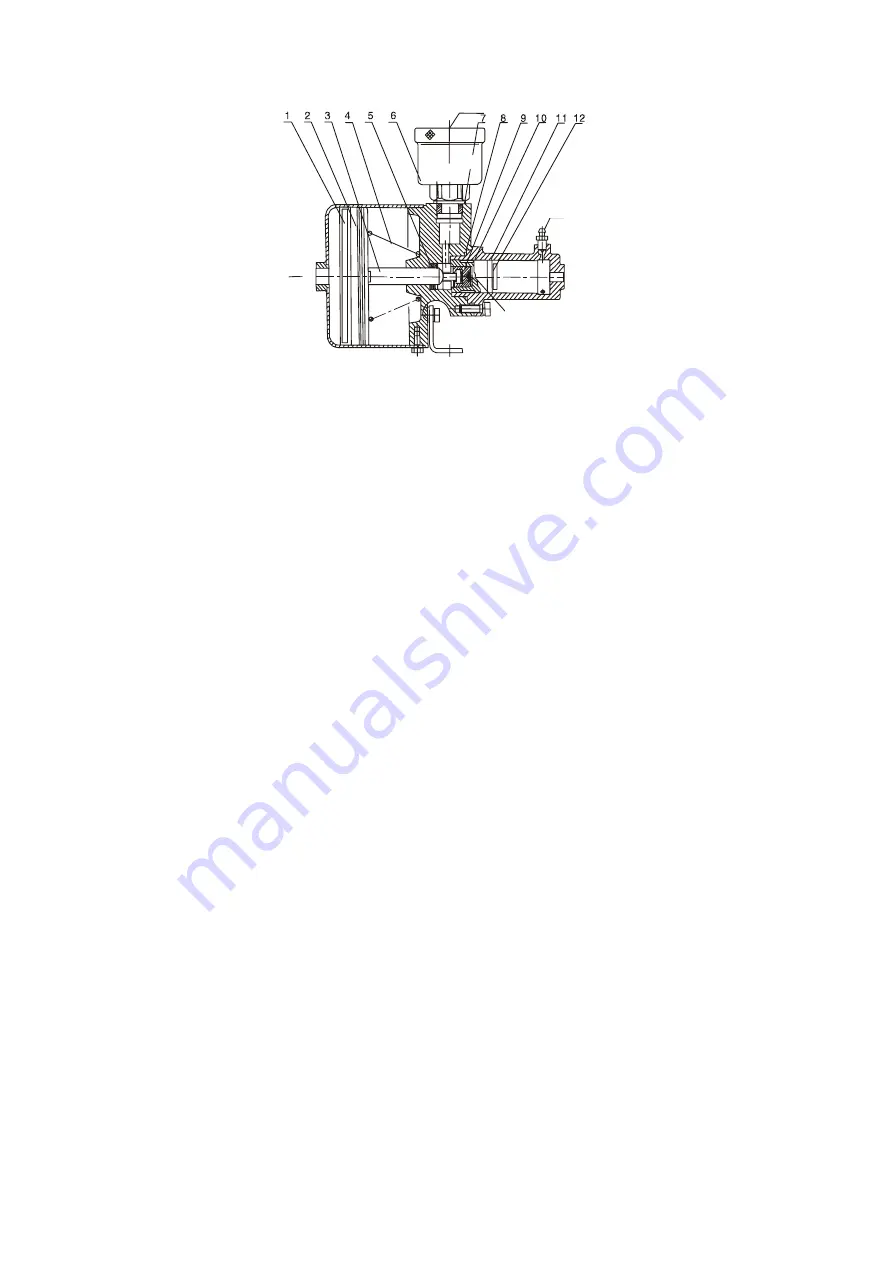

Fig. 3-24

Working principle: The structure is shown in Fig. 3-24. The booster pump is a gas pushed oil booster

comprising cylinder and hydraulic master pump. During working, the air entering through air inlet

pushes the push rod piston assembly forward and the push rod pushes the push rod seat assembly.

The oil intake valve seals the oil-filling hole in the hydraulic piston so that a hydraulic pressure is built

up in the hydraulic cylinder and the outputted hydraulic pressure is 10 X90% times as much as the

inputted air pressure. When the air pressure is relieved, under the action of return spring, the oil-filling

hole is opened and the hydraulic oil returns to the oil cup through the oil-filling hole.

E. Structure of brake:

Hydraulic caliper disc brake features great braking torque and high speed. Every axle is equipped with

two auxiliary brakes. Brake consists of inner and outer caliper bodies, piston, brake pad and brake disc

and is fastened to the drive axle housing. Brake disc is fastened to hub, and they make the counter

rotation to the axle housing shaft pipe.

Working principle:

During braking, high pressure brake fluid flows from brake pipe into hydraulic chamber behind piston

through caliper body to drive pistons on both sides to push brake pad to the central position, so that

the rotating brake disc fitted to hub is clamped to produce torque of frictional resistance to brake the

vehicle.

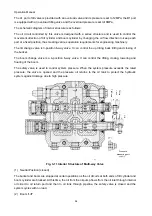

3.

Usage and maintenance of service brake system:

Frequent and proper maintenance of service brake system plays an important role in ensuring braking

performance and improving driving safety.

(1) Frequently check the system for leakage and various connectors and connection parts for

looseness. There shall be no leakage for the air and oil channel systems.

(2) The high-temperature resistant synthetic brake fluid of 719 type(conforming to the standard of

HZY3 product in “GB12981-2003 Brake Fluid of Motor Vehicle”) is preferred. In case of change, only

use vegetable brake fluid and add the brake fluid of new brand after cleaning the original brake fluid.

Timely refill the brake fluid when the level is low. For each filling, a filter bowl shall be used and the

level shall be 20-25mm away from the oil filler. The brake fluid shall not be mixed with mineral oil and

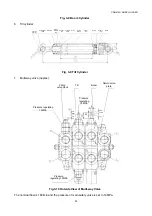

Oil filling port

Oiloutlet

Bleed

screw

Air inlet

Oilinlet

Vacuum air hole