CDM816D WHEEL LOADER

47

be adjusted through increasing/reducing the number of adjusting shims at bearing bush and of the

adjusting nuts at the bearings on both sides of the differential.

2.

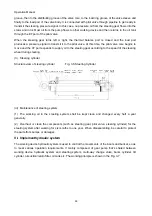

Adjustment of wheel-side hub bearing clearance:

Tighten the round nut until the hub can rotate hardly, and then turn the round nut by 1/10 circle

reversely. After the operation, the hub shall rotate freely without seizing and be free from obvious axial

clearance and deflection. Finally, clip the thrust shim into the slot of round nut for locking.

(iv) Maintenance:

1.

Before assembling the drive axle, fill a proper amount of lubricating oil (recommended lubricating

oil is GL-4 85W/90 heavy-duty vehicle gear oil). Ensure to fill the oil from the axle package oil level

hole in the middle of axle housing and from the wheel oil port on both sides.

Filling capacity: 3kg at axle package, 2.5kg at wheel rim on each side.

2.

After the new axle operating with the main engine for 50 h, change the lubricating oil. The axle

should be cleaned before changing oil.

Check main reducer housing, wheel-side end cover for early heating; if any, check whether the oil level

meets requirements.

Check the fastening of all fasteners; if any fastener is loosened, retighten it.

Check for abnormal noise during operation; if any, stop the loader for troubleshooting.

Check each oil seal for seepage; if any, replace with a new oil seal.

3.

Change with new lubricating oil every 1,200 h for the main reducer and wheel-side reducer, and

note that the required lubricating oil shall be used according to different regions and seasons.

When changing lubricating oil, drain the waste oil whenit’s hot, and remember to checkthe metallic

impurity content in the waste oil.

Perform disassembly inspection every 2,400 h. (Check the clearance, meshing and wear of main

reducer spiral bevel gear pair; check the wear of differential gear, bevel gear shim, wheel side gear,

wheel-side planetary gear roller needle and bearing.)

If the tyre is damaged, the 4 wheels shall be replaced normally, and at least 2 wheels for the same axle

shall be replaced to ensure normal operation of the differential.

(v) Fault analysis &solutions:

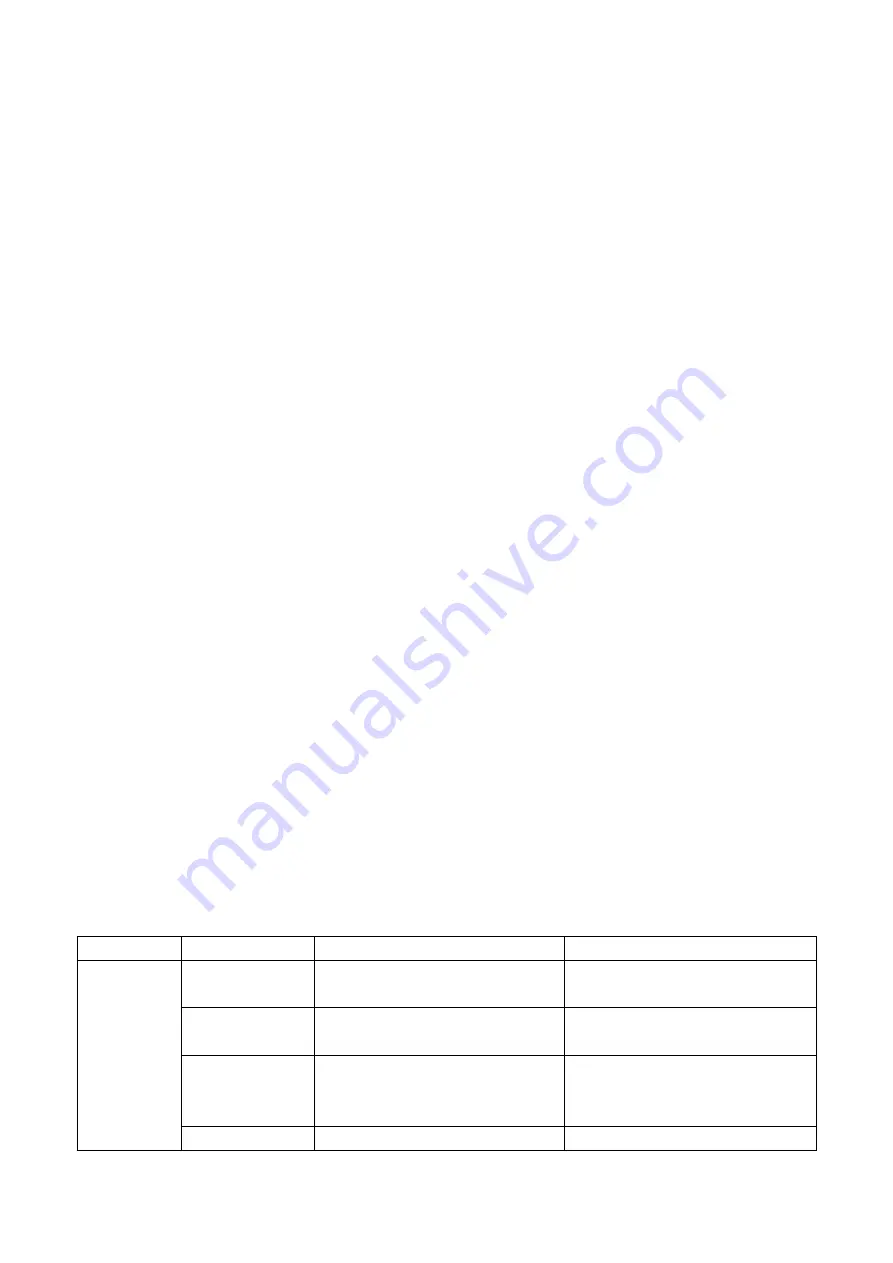

Items

Faults

Causes

Solutions

Main

reducer and

differential

Loud noise

1. Excessive gear clearance

2.

Wear of rolling bearing

Adjust gear clearance

Replace bearing

Early heating of

housing

Poor lubrication, no or excessive

lubricating oil

Fill oil to specified level

Periodic

abnormal noise

1. Teeth collision on gear

2.

Foreign matters inside

3.

Looseness of fasteners

Replace gear

Drain oil for inspection

Tighten fasteners

Differential

Broken cross axle

Replace cross axle