CDM816D WHEEL LOADER

45

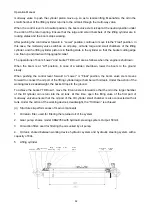

up to get a stable control of oil pressure (1.2~1.5 MPa).

The oil returned from torque converter flows into the cooler for cooling at first and then into the

transmission for lubrication and cooling through lubricating oil pressure valve which has a pressure of

0.10~0.20 MPa (1-2kg/cm

2

).

(iii) Maintenance of torque converter/transmission

Whether the torque converter and transmission work properly is related to the performance of the

whole loader, therefore, in addition to normal maintenance, the following items shall be noted:

1.

Working oil level in transmission

Before starting the engine, check the two drain plugs on the right of the transmission, with upper one at

the max. level and lower one at min. level.

2.

Pressure of working oil in torque converter/transmission

The inlet and outlet pressures of torque converter have been adjusted in manufacturing factory. The

pressure reading of the working oil in transmission on the pressure gauge shall be within 1.2~1.5MPa

after running the engine, in case of abnormality, check it.

3.

Oil temperature

The max. oil temperature shall not exceed 120

℃

during normal operation and driving, if it is exceeded,

stop the loader to cool and check.

4.

After running-in period, the oil shall be replaced with new one for the transmission after driving for

600 hours generally; however, if oil deterioration or impurity mixture is found during check, wash,

check and replace with new oil of specified brand.

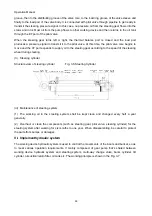

IV. Drive axle

The drive axles include front axle and rear axle for which the only difference lies in the hand of spiral of

spiral bevel gear of main reducer pair. The driving spiral bevel gear of front axle is left-hand and that of

rear axle is right-hand. However, thestructures are the same.

(i) Main structural features:

The drive axles are designed with double reduction drive structures. The first–stage reduction gear is

driven by spiral bevel gear, which features high input torque, high transmission efficiency and stable

work; the second-stage reduction gear is designed with a planetary reduction drive structure (NGW)

with good overall movement rigidity and stable output speed. Between two reduction gears, a

full-floating axle shaft is used to transmit power, thus overcoming the impact of axle housing on axle

shaft drive during work and transformation.

(ii) Working principle (see Fig. 3-4)